Control valves are essential components in fluid handling systems, regulating flow rates, pressure, and direction. Among the various types of control valves, V-port ball valves and globe control valves are widely used in industrial applications. While both serve flow control purposes, they differ significantly in design, performance, and suitability for specific applications.

This article explores the key differences between V-port ball valves and globe control valves, covering their construction, flow characteristics, shutoff tightness, and ideal use cases.

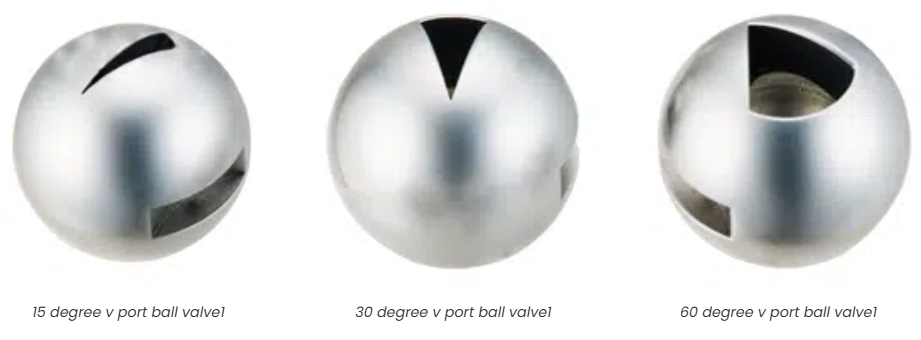

V-port ball valves are a specialized type of ball valve designed for coarse flow control while maintaining reliable shutoff capabilities. Unlike standard ball valves with a circular bore, V-port ball valves feature a characterized "V"-shaped bore, which modifies the flow curve for better control.

The ball has a wedge-shaped (V-notch) port instead of a circular opening.

The angle of the V-port can vary (commonly 30°, 60°, or 90°), affecting flow control precision.

A 30° V-port provides finer, tapered control.

60° and 90° V-ports allow higher flow rates (higher Cv value) but with less precision.

The valve operates via a 90-degree rotary motion, making it more compact than linear-motion valves like globe valves.

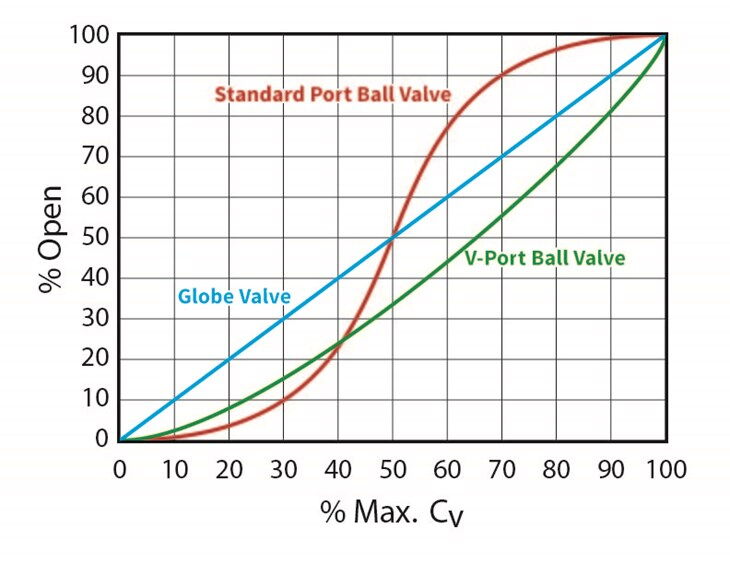

The V-shaped bore linearizes the flow curve, making it more suitable for throttling applications compared to standard ball valves.

However, the flow increase is not perfectly linear with rotation, making it less precise than globe valves for fine control.

Provides bubble-tight shutoff (zero leakage) due to the floating ball design.

When closed, upstream pressure pushes the ball against the downstream seat, enhancing sealing.

Compact design (rotary motion requires less space).

Higher flow capacity (Cv) compared to globe valves of the same size.

Reliable shutoff (bubble-tight sealing).

Good for coarse to moderate flow control.

Less precise flow control compared to globe valves.

Potential for uneven seat wear in mid-throttle positions.

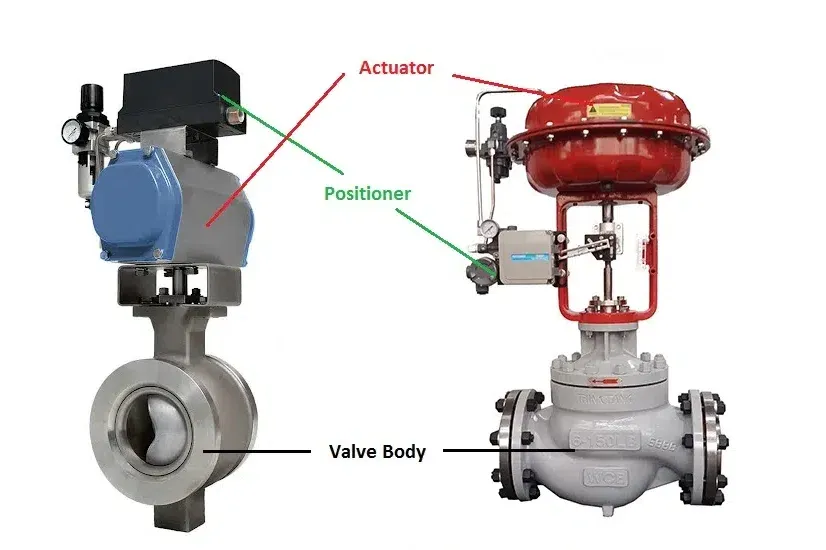

Globe control valves are linear-motion valves traditionally preferred for precise flow regulation. They consist of a movable plug (or disc) and a stationary ring seat, allowing for fine adjustments in flow rate.

The valve stem moves up and down to adjust flow, requiring more installation space than rotary valves.

Provides a more linear flow curve, enabling high-precision control.

The plug-and-seat design allows for smoother throttling compared to V-port ball valves.

Typically has a higher pressure drop than V-port ball valves because fluid must change direction inside the valve body.

The force exerted on the stem requires a larger actuator for proper seating.

Generally does not provide bubble-tight shutoff.

Leakage rates comply with ANSI FCI 70-2 standards (Class II, III, IV, V, or VI).

Superior flow control precision.

Better for high-pressure applications.

More consistent performance in mid-throttle positions (no uneven wear like V-port valves).

Larger and heavier due to linear actuation.

Higher pressure drop reduces energy efficiency.

Not ideal for tight shutoff (unlike V-port ball valves).

|

Feature |

V-Port Ball Valves |

Globe Control Valves |

|

Actuation Type |

Rotary (90° turn) |

Linear (up and down motion) |

|

Flow Coefficient (Cv) |

Higher (more flow for the same valve size) |

Lower (smaller flow capacity) |

|

Flow Control Precision |

Moderate (good for coarse control) |

High (ideal for precise throttling) |

|

Shutoff Tightness |

Bubble-tight (zero leakage) |

Not bubble-tight (ANSI leakage classes) |

|

Pressure Drop |

Lower (better for high-flow systems) |

Higher (more energy loss) |

|

Installation Space |

Compact (rotary motion) |

Larger (requires linear stem movement) |

|

Wear in Mid-Positions |

Can experience uneven seat wear |

More consistent performance |

|

Actuator Force Needed |

Lower (easier to automate) |

Higher (requires larger actuators) |

When selecting between V-port ball valves and globe control valves, consider these critical factors:

Opt for a V-Port Ball Valve when you need:

• Moderate flow control in industrial processes

• Bubble-tight shutoff (zero leakage capability)

• Compact installation due to space limitations

• High flow capacity with minimal pressure drop

Choose a Globe Control Valve for:

• Precision flow regulation in chemical dosing or HVAC

• High-pressure systems requiring robust performance

• Smooth, linear throttling for consistent process control

• Applications where mid-position wear is a critical concern

The right choice depends on your specific requirements for control precision, leakage tolerance, space constraints, and system pressure. V-port valves excel in shutoff and compact designs, while globe valves offer superior throttling accuracy. Evaluate your operational needs carefully to select the optimal valve solution for your application.

For maximum efficiency, always match valve characteristics to your system's flow control demands and environmental conditions.

Both V-port ball valves and globe control valves have distinct advantages depending on the application.

V-port ball valves excel in compact, high-flow systems requiring shutoff reliability.

Globe control valves are better for precise throttling and high-pressure applications.

Understanding their differences ensures optimal valve selection for efficiency, performance, and cost-effectiveness in industrial and process control systems.