In modern industrial automation, precision, efficiency, and safety are paramount. Among the many components that enable smooth operation in process systems, electric or motorized globe control valves play a critical role. These valves regulate the flow of liquids, gases, and steam with high accuracy, making them indispensable across diverse sectors such as oil and gas, chemical processing, power generation, water treatment, and pharmaceuticals.

Choosing the right motorized globe control valve is not as straightforward as simply matching pipe size or pressure. The decision involves multiple factors, including the application’s flow requirements, operating environment, valve type, material selection, and automation capabilities. With industrial systems becoming more advanced and integrated into smart networks, selecting a suitable valve can significantly influence both performance and overall operating costs.

This article explores the working principle of motorized globe valves, their types, key specifications, material options, and advantages. It will also provide practical guidance on how industries can evaluate and select the right valve for long-term efficiency and reliability.

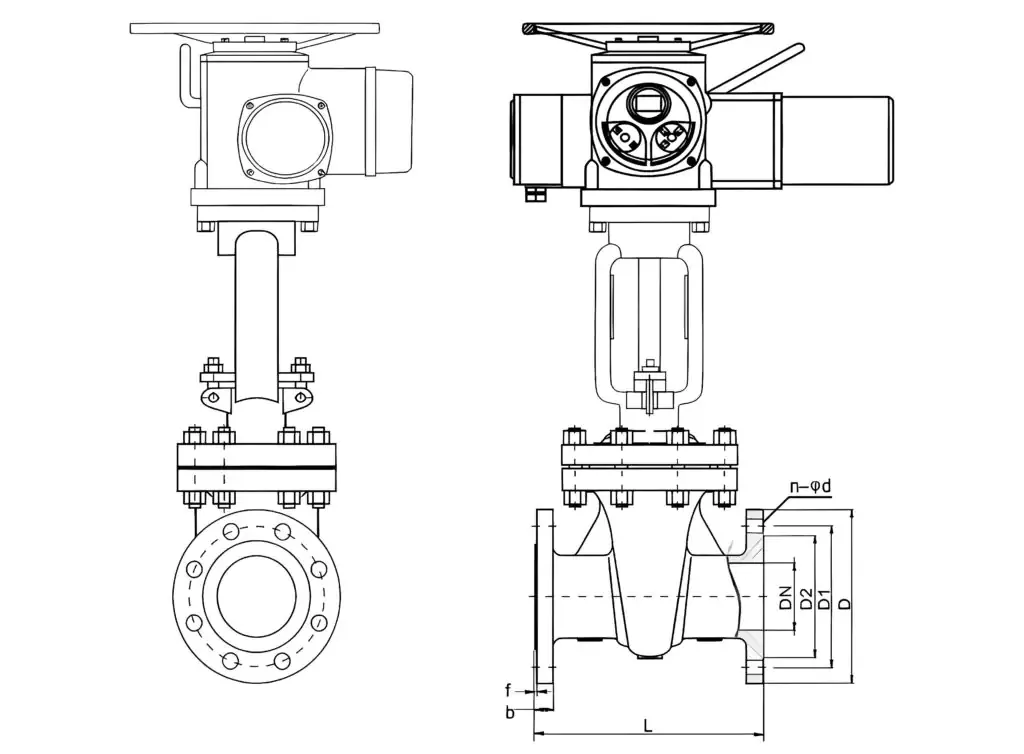

A globe valve is designed with a movable disk (plug) and a stationary ring seat in a generally spherical body. The design allows for precise throttling control, which sets it apart from many other valve types. When combined with an electric actuator, the valve becomes motorized, enabling automatic and remote operation.

The actuator uses electric power to drive the valve stem, exerting torque that applies downward pressure on the sealing surface. Depending on the actuator’s input signals, the valve can:

Close fully to stop the flow of media.

Open fully to allow maximum flow.

Throttle at intermediate positions for precise flow regulation.

By modulating the valve stem’s movement, the actuator ensures that the flow rate, pressure, or temperature within the system stays within desired ranges. This makes motorized globe control valves particularly valuable in continuous process industries where precise regulation is critical for safety, quality, and efficiency.

Selecting the right valve requires an understanding of the application’s unique needs. Below are some of the most important considerations:

Precise throttling: If your process requires accurate control of flow rates or pressures, globe valves are ideal. Their seat and plug design enables fine adjustments.

On/off service: While globe valves can handle on/off applications, they excel in modulating control compared to gate or ball valves.

Pressure and Temperature: Valves must withstand the maximum system conditions without risk of leakage or deformation.

Fluid Type: The chemical composition of the media (corrosive, abrasive, or clean) directly influences material and sealing choices. For example, steam applications require high-temperature materials, while corrosive chemicals call for stainless steel or exotic alloys.

Corrosion risks: Valves exposed to saltwater, chemicals, or outdoor conditions need corrosion-resistant materials.

Temperature extremes: If installed outdoors in very hot or cold climates, the actuator and valve body must tolerate these fluctuations.

Hazardous locations: Some installations demand explosion-proof actuators or enclosures.

Motorized globe control valves come in several configurations. Choosing the correct type can enhance system performance and longevity.

Features: Provide tight shut-off with a single sealing surface.

Applications: Ideal for processes requiring precise flow control and isolation.

Limitations: Slightly lower flow capacity due to the single seat design.

Features: Incorporate two sealing surfaces, allowing higher flow capacity.

Applications: Best suited for large flow rates where shut-off is less critical.

Limitations: Not as effective for tight shut-off compared to single-seated designs.

Features: Designed for mixing or diverting flow, available in “T” or “L” port designs.

Applications: HVAC systems, water treatment, and processes requiring flow direction control or mixing of two fluids.

Limitations: More complex design, typically more expensive.

When evaluating a motorized globe control valve, several specifications ensure the valve will perform reliably in your system.

The valve must match the pipeline diameter to maintain efficiency. Oversized valves may cause poor control accuracy, while undersized valves can restrict flow.

Rated according to standards such as ANSI or PN classes. Always select a valve rated equal to or higher than the system’s maximum pressure.

Choose a valve capable of withstanding both the highest and lowest expected operating temperatures. This is vital in steam, cryogenic, or high-temperature chemical applications.

Cv defines the flow capacity of the valve. Understanding this parameter ensures the valve delivers the required flow while maintaining stability and minimizing pressure drops.

The choice of material has a direct impact on performance, durability, and cost.

Stainless Steel (SS316/SS304): Excellent corrosion resistance, ideal for chemicals, seawater, and pharmaceuticals.

Carbon Steel (WCB): Strong and economical, suitable for high-pressure steam and water applications.

Brass/Bronze: Commonly used in HVAC, water treatment, and low-pressure systems.

Exotic Alloys (Hastelloy, Monel, Titanium): Required for aggressive media like acids, chlorides, or seawater.

PTFE (Teflon): Good chemical resistance and low friction, suitable for medium temperatures.

Metal-to-Metal Seals: Withstand extreme temperatures and pressures, used in steam and power plants.

Elastomers (EPDM, NBR, Viton): Flexible sealing options for specific fluids and temperature ranges.

The valve’s design allows accurate throttling with minimal fluctuations. This precision makes them ideal for industries like pharmaceuticals and power generation, where consistency is critical.

Motorized actuators enable remote and automated control, eliminating the need for manual operation. In hazardous or hard-to-reach areas, this ensures both safety and efficiency.

Modern valves can be integrated with IoT-based monitoring systems, SCADA, or DCS. This allows real-time tracking of flow conditions, predictive maintenance, and process optimization.

With proper material selection, these valves can handle harsh chemicals, high pressures, and extreme temperatures. Their long service life reduces downtime and maintenance costs.

Advanced actuators are designed to consume less energy, lowering operational costs. In systems with frequent valve movements, energy-efficient actuators make a significant difference.

Oil and Gas: Used in refineries, pipelines, and offshore platforms for regulating crude oil, natural gas, and steam.

Chemical Processing: Provide accurate control of corrosive and hazardous chemicals.

Power Generation: Manage steam flow in boilers and turbines to optimize efficiency and safety.

Water and Wastewater Treatment: Control the flow of clean and treated water, as well as chemical dosing.

Pharmaceutical Manufacturing: Maintain sterile environments by precisely regulating process fluids.

HVAC Systems: Ensure efficient distribution of hot and cold water in heating and cooling systems.

Although motorized globe control valves are built with robust materials and advanced engineering, regular maintenance is essential to ensure consistent performance, safety, and long service life. By adopting proactive care practices, industries can minimize downtime, avoid costly repairs, and maintain precise control over process operations. Below are key maintenance guidelines and best practices.

Routine inspections are the first line of defense against unexpected valve failures. Operators should periodically examine the valve body, actuator, seats, plugs, and seals for signs of wear, corrosion, or damage. Early detection of issues such as scratches on the sealing surface, loose connections, or actuator misalignment can prevent more serious operational problems. Visual checks should be supplemented with functional testing to confirm that the valve opens, closes, and throttles as intended.

The actuator and moving parts of the valve require adequate lubrication to function smoothly. Without it, friction can increase, leading to excessive wear or mechanical failure. Lubricants should be selected according to the manufacturer’s recommendations and applied at appropriate intervals. Special attention should be given to environments with high humidity, dust, or temperature extremes, as these conditions can degrade lubrication more quickly.

Over time, actuators may drift from their calibrated settings, reducing the valve’s ability to regulate flow with precision. Recalibrating actuators on a scheduled basis ensures that control signals correspond accurately to valve positions. This step is particularly important in industries such as power generation, pharmaceuticals, and chemical processing, where even small deviations in flow control can have significant consequences on product quality and safety.

Seals, gaskets, and packing are consumable parts that naturally wear out during operation. At the first signs of leakage, hardening, or deformation, these components should be replaced promptly to avoid system inefficiency or unplanned shutdowns. Using original spare parts from trusted suppliers guarantees compatibility and reliability.

Establishing a preventive maintenance schedule helps organizations plan inspections, lubrication, and calibration in advance. Keeping detailed records of maintenance activities, parts replacements, and valve performance also assists in predicting service life and budgeting for future upgrades.

Selecting the right motorized globe control valve is a strategic decision that affects not only the immediate performance of an industrial system but also its long-term efficiency, safety, and operating costs. By carefully evaluating factors such as flow requirements, operating conditions, valve type, material compatibility, and integration capabilities, industries can ensure they choose a valve that delivers optimal results.

With the growing adoption of automation and smart technologies, motorized globe valves have become more than just flow regulators—they are now integral components of intelligent process management systems. Their precision, durability, and adaptability make them a cornerstone of modern industry, and when chosen correctly, they provide years of reliable and efficient service.