Multi-turn electric globe valves have revolutionized industrial flow control, providing advanced automation and precision in regulating fluid flow. Unlike traditional manual globe valves, these innovative valves are operated by electric actuators that rotate the valve stem to control opening and closing. This electric actuation system enables remote and automated operation, making these valves a key component in industries where frequent adjustments and precise control of flow are critical.

The core feature of multi-turn electric globe valves is the electric actuator, which allows for precise positioning of the valve disc or plug within the valve body. By controlling the motor’s rotation, operators can finely adjust the flow rate, ensuring accurate and repeatable control over fluid movement. This level of precision is essential in industries like water treatment, HVAC systems, power generation, and chemical processing, where maintaining exact flow parameters is vital for both operational efficiency and safety.

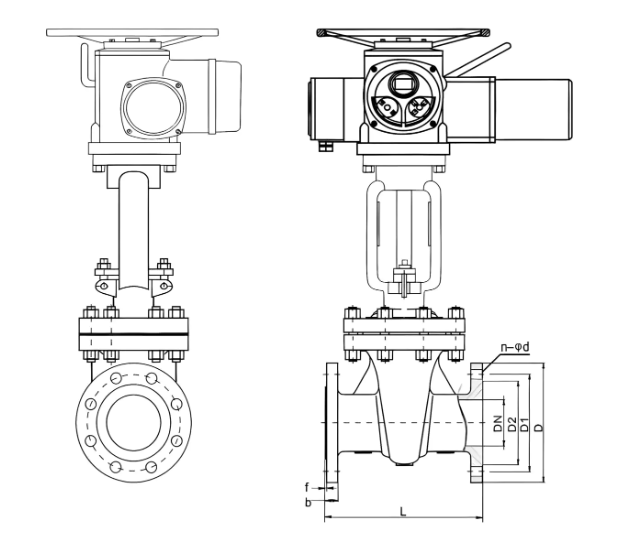

Multi-turn electric globe valves are built to withstand harsh conditions, with designs incorporating high-quality materials such as stainless steel 316 or cast iron. The robust construction ensures durability, corrosion resistance, and long-term performance even in demanding environments. The bolted bonnet and non-rising stem configuration provide a secure seal, reducing the risk of leaks and enhancing overall system safety. Additionally, the flanged connections on both ends make installation and maintenance straightforward, allowing these valves to be easily integrated into existing pipelines and systems.

Model: Multi-Turn Electric Globe Valves

Size Range: 2 Inch to 40 Inch

Pressure Range: 1.6MPa to 6.4MPa

Materials: Stainless Steel 304/316 or Cast Iron

These valves are engineered to deliver precise flow control across a wide range of applications, accommodating various pressures and operational demands. Their reliability and efficiency make them ideal for industries that require consistent, high-performance flow regulation.

In water treatment facilities, multi-turn electric globe valves are essential for controlling flow rates, adjusting chemical dosing, and ensuring the efficient operation of filtration and purification systems.

These valves play a crucial role in HVAC systems, where precise control of water, steam, or refrigerant flow is necessary to maintain comfortable and energy-efficient indoor environments.

Power plants rely on multi-turn electric globe valves to regulate steam and water flow in boilers and turbines, improving overall efficiency and safety in energy production.

In the chemical industry, these valves manage the flow of corrosive or hazardous substances, ensuring safe and precise handling of fluids throughout production processes.

Each multi-turn electric globe valve is subjected to rigorous testing to meet industry standards, including API 600 Pull test protocols for the stem/wedge connection. This stringent quality assurance guarantees that the valves can perform reliably under pressure and in critical applications where precision control is necessary.

The flanged connections on both ends of the valve simplify installation and reduce maintenance downtime, allowing operators to quickly replace or service valves without disrupting system operations. This ease of maintenance, combined with the reliability of electric actuation, further enhances the valve’s appeal in industrial settings that prioritize operational uptime and efficiency.

Multi-turn electric globe valves are a vital component in modern industrial automation, offering unparalleled precision and control over fluid flow. Their electric actuation system, coupled with a durable and corrosion-resistant design, makes them an ideal choice for industries such as water treatment, HVAC, power generation, and chemical processing. As industrial operations increasingly move towards automation, these valves provide the reliability and performance needed to ensure efficient, safe, and effective flow control in critical applications.