In industrial process control systems, the pneumatic single-seated control valve plays a crucial role in maintaining stability, precision, and safety across a wide range of fluid-handling applications. Known for its simple structure, compact design, and accurate regulating performance, this valve type is a fundamental component in systems that require precise control of flow, pressure, and temperature.

A single-seated control valve is characterized by a single valve plug (spool) and a single seat, through which the controlled fluid passes. The design is engineered to provide excellent sealing performance and sensitive response to pneumatic actuation, ensuring consistent process regulation even under demanding operating conditions.

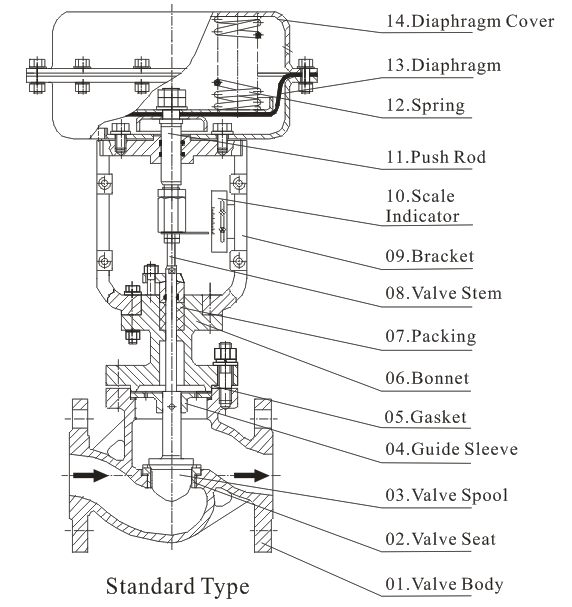

Structurally, the valve consists of a valve body, valve seat, valve plug (spool), stem, and an upper bonnet. The upper cover serves as a pressure-retaining element for the packing while also functioning as a central positioning guide for the stem and plug assembly. The seat and bonnet alignment ensures accurate centering, allowing the valve plug to move smoothly in response to pneumatic actuator signals.

When the valve plug moves, the flow area changes, adjusting the flow rate of the process medium. This action translates a control signal—typically air pressure—from the actuator into a mechanical movement that modulates flow precisely, achieving the desired process control objective.

The valve stem and plug are generally fixed using connecting pins or interference fits to ensure structural integrity under operational loads. In most designs, the plug is top-guided by the bonnet to maintain alignment and reduce vibration during operation. For applications requiring enhanced stability—especially under high-pressure conditions—both top and bottom guidance may be used. In smaller valves or those designed for very low flow rates, seat-guided configurations are preferred to maintain tight shutoff and smooth operation.

A pneumatic single-seated control valve operates by converting compressed air pressure from a control signal into linear mechanical motion that adjusts the position of the valve plug. The actuator, usually a pneumatic diaphragm or piston type, exerts force on the valve stem, which moves the plug up or down relative to the valve seat.

When the plug moves downward, the flow area decreases, restricting the fluid passage. This configuration is referred to as a direct-acting or positive body valve.

Conversely, when the plug moves upward, the flow area increases, allowing greater flow—this is called a reverse-acting or reverse body valve.

By reversing the plug’s orientation on the stem, the same valve body can be configured as either air-to-open (fail-close) or air-to-close (fail-open), depending on process requirements. This versatility allows operators and engineers to adapt the valve to suit different control strategies and fail-safe positions.

For smaller valves (typically DN < 25 mm), only positive body configurations are usually available. In these cases, a counter-acting actuator is used for gas-open control, ensuring the valve opens or closes correctly in response to pneumatic signal variations.

Pneumatic single-seated control valves combine robust mechanical design with precision engineering. Their construction and operation offer several technical and operational advantages:

The single seat and plug configuration minimize internal components, making the valve easier to assemble, maintain, and inspect.

The single-seat structure provides excellent sealing performance, ensuring minimal leakage even under high differential pressures.

The direct relationship between actuator displacement and plug movement ensures precise modulation of flow.

Top-guided or dual-guided designs minimize plug vibration, reducing wear and improving longevity.

Fewer moving parts and straightforward packing systems simplify maintenance and prolong service life.

Suitable for controlling liquids, gases, and steam across various industries, from chemical to petrochemical, power generation, and water treatment.

Available in a variety of body and trim materials—such as carbon steel, stainless steel, bronze, or Hastelloy—to meet specific process conditions.

The chemical processing sector relies heavily on pneumatic single-seated control valves to maintain tight control over critical process parameters such as temperature, pressure, and flow rate. In these facilities, precision is not just desirable—it is essential for product quality, process safety, and operational efficiency.

These valves are particularly effective in reactor temperature control systems, where even slight fluctuations in thermal conditions can affect reaction kinetics and product outcomes. The single-seat design provides tight shutoff capability, preventing unwanted cross-contamination or backflow that could trigger undesired chemical reactions.

Materials selection is crucial in chemical environments. To handle corrosive chemicals and high-temperature media, single-seated control valves are often manufactured from 316 stainless steel, Hastelloy, Monel, or other special alloys with corrosion-resistant coatings. This ensures long-term durability and maintains the dimensional stability of the valve seat and plug under continuous exposure to aggressive chemicals.

The pneumatic actuator system is another critical component that ensures responsive and accurate control. Pneumatic actuation allows rapid response times, often within seconds, making these valves suitable for processes that demand immediate adjustments when deviations in temperature, pressure, or flow occur.

In modern chemical plants, these valves are integrated into Distributed Control Systems (DCS), allowing precise real-time control through cascade or ratio control loops. For example, a cascade system may use the valve to regulate coolant flow in response to changes in reactor temperature, maintaining the process at optimal conditions.

By ensuring stable, responsive, and leak-free performance, pneumatic single-seated control valves contribute significantly to the safety, consistency, and energy efficiency of chemical manufacturing operations.

While chemical processing represents one of the primary uses, pneumatic single-seated control valves also play vital roles in other industries:

Petrochemical and Refining: Used in distillation columns, pressure control systems, and fuel gas regulation for their ability to handle high-pressure differentials and maintain tight shutoff.

Power Generation: Employed in steam and condensate control systems for boilers and turbines, ensuring stable load operation.

Pharmaceutical Manufacturing: Provide hygienic and precise control in sterile systems, often with polished stainless-steel internals and FDA-compliant sealing materials.

Water Treatment and Waste Management: Control flow and pressure in filtration, desalination, and effluent treatment plants.

Food and Beverage Processing: Used to control heating, mixing, and ingredient dosing processes, ensuring consistent product quality.

Across all these industries, the combination of reliable actuation, tight sealing, and precise modulation makes pneumatic single-seated control valves a cornerstone of modern automation systems.

As industries increasingly pursue sustainability and energy efficiency, pneumatic single-seated control valves have evolved to meet environmental goals while maintaining operational excellence.

Low-emission packing systems—such as PTFE or graphite-based designs—significantly reduce fugitive emissions, which are small leaks of volatile gases from valve stems or seats. This not only helps facilities comply with stringent environmental regulations (such as ISO 15848 and EPA standards) but also minimizes product loss and enhances plant safety.

Modern designs also feature energy-efficient actuators that optimize compressed air usage. Since compressed air generation is energy-intensive, minimizing air consumption reduces both operating costs and carbon footprint.

Valve trim design plays a key role in overall system efficiency. Advanced trims are engineered to reduce pressure drops across the valve, thereby lowering pumping energy requirements. In large process systems, even minor improvements in valve flow coefficients (Cv) can translate into substantial energy savings.

Precision control enabled by pneumatic valves also contributes to process optimization. By maintaining steady-state conditions, plants can reduce waste generation, improve product yield, and minimize energy consumption per unit of production. When integrated with plant-wide control systems, these valves support coordinated energy management strategies that enhance the efficiency of entire production facilities.

Ultimately, pneumatic single-seated control valves are not only mechanical components—they are strategic tools for environmental responsibility, aligning industrial performance with sustainability objectives.

The evolution of automation and smart control technologies has elevated the functionality of pneumatic single-seated control valves. Today’s systems incorporate digital positioners, smart sensors, and communication interfaces compatible with protocols like HART, Foundation Fieldbus, and Profibus.

Digital positioners enhance valve performance by providing real-time feedback, auto-calibration, and diagnostic capabilities. This ensures the valve maintains precise positioning accuracy, reduces hysteresis, and minimizes overshoot during operation.

Moreover, integrated diagnostics allow predictive maintenance—monitoring parameters such as stem friction, actuator pressure, and valve seat condition. By identifying early signs of wear or leakage, maintenance teams can schedule interventions before failures occur, reducing downtime and maintenance costs.

In advanced process control environments, pneumatic single-seated control valves are also linked with control system analytics and machine learning algorithms, which continuously optimize valve tuning parameters to improve overall process stability and efficiency.

Safety remains a primary consideration in valve design and application. Pneumatic single-seated control valves are often equipped with fail-safe features that ensure the valve automatically returns to a safe position during power or air supply failures. Depending on the process requirements, these may be air-to-open (fail-close) or air-to-close (fail-open) configurations.

Additionally, features such as position limit switches, manual override mechanisms, and spring-return actuators provide redundancy and operational assurance. These safety enhancements protect both personnel and equipment, particularly in hazardous or high-pressure environments.

The pneumatic single-seated control valve remains one of the most trusted and versatile components in industrial automation systems. Its simple yet robust structure, tight shutoff capability, and precise control characteristics make it indispensable across industries ranging from chemical processing and petrochemicals to power generation and water treatment.

By combining mechanical efficiency with digital intelligence, today’s single-seated control valves support energy-efficient, environmentally responsible, and high-performance operations. Their ability to deliver consistent control accuracy, minimize emissions, and integrate seamlessly into advanced automation systems ensures that they will continue to play a central role in the next generation of industrial process control.