In modern industrial processes, precise flow control is critical for optimizing efficiency, safety, and product quality. Among the wide variety of valve technologies available, the pneumatic V-port ball valve has emerged as a versatile solution for industries ranging from chemical processing to power generation, food and beverage, pharmaceuticals, and more. This article explores what a pneumatic V-port ball valve is, how it works, its key components, benefits, applications, market trends, standards, challenges, and the future outlook for this essential industrial device.

Industrial processes often involve the movement of liquids, gases, or steam under controlled conditions. Controlling flow rate, pressure, or temperature accurately ensures product consistency, minimizes waste, and protects equipment. While traditional ball valves offer simple on/off control, V-port ball valves provide enhanced flow regulation capabilities due to their unique design. When coupled with pneumatic actuation, these valves combine precision with automation, enabling remote operation, fast response, and integration with modern control systems.

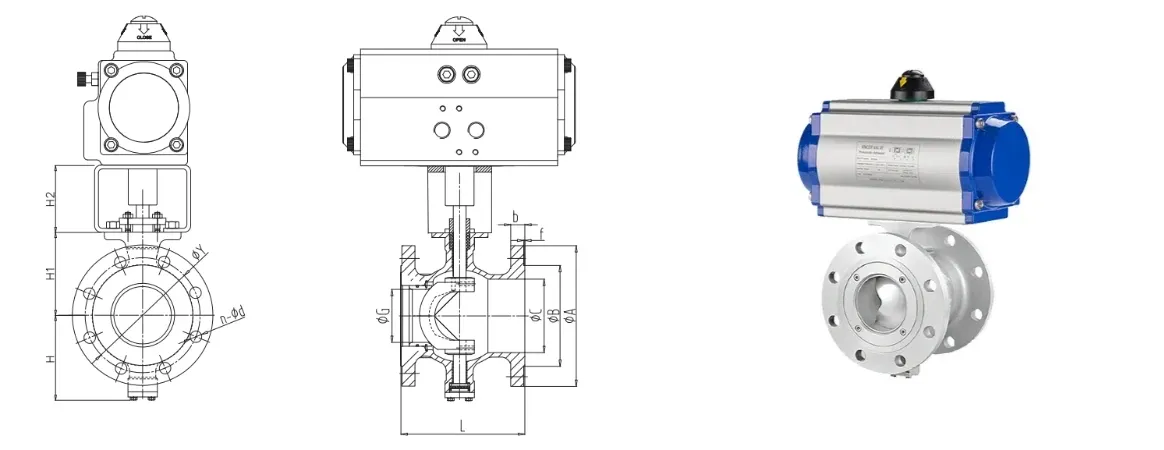

A pneumatic V-port ball valve is a quarter-turn valve that uses a ball with a V-shaped opening through its core to control flow. Unlike standard ball valves that allow rapid full-open or full-close operation, the V-port design enables accurate throttling by modulating flow through the gradually expanding or narrowing V-shaped passage.

Key characteristics include:

Pneumatic actuation: Operated using compressed air for fast, remote, and automated control.

V-port ball: A ball with a V-shaped opening or cut that allows precise flow adjustment.

Quarter-turn operation: Rotates 90° to move from fully closed to fully open.

Industrial-grade construction: Typically made from stainless steel, carbon steel, or specialized alloys.

The combination of pneumatic automation and V-port design provides both on/off functionality and fine flow control, making it ideal for dynamic industrial environments.

A typical pneumatic V-port ball valve consists of several integral components:

Valve body: Provides structural support and houses the ball. Materials include stainless steel, carbon steel, or alloy steel for high-pressure applications.

V-port ball: The core component with a V-shaped orifice that enables linear or equal-percentage flow control.

Seats are made of PTFE, reinforced PTFE, or metal for high-temperature and high-pressure applications.

Seals prevent leakage and ensure tight shutoff, even in demanding conditions.

Converts compressed air into mechanical motion to rotate the ball.

Single-acting (spring return): Uses air to open or close, with a spring returning the valve to its default position.

Double-acting: Uses air pressure for both opening and closing, providing precise control.

Positioners allow the valve to be controlled precisely to any point between fully open and fully closed.

Digital or analog feedback signals can integrate with PLC or SCADA systems for automated process control.

Unlike standard ball valves that offer abrupt opening and closing, V-port ball valves provide controlled, proportional flow:

Flow Modulation: The V-shaped opening allows fluid to pass gradually as the ball rotates.

Flow Characteristics:

Linear V-port: Flow changes approximately linearly with rotation.

Equal-percentage V-port: Flow changes exponentially, ideal for processes requiring finer control at lower flow rates.

Automation via Pneumatics: Compressed air actuates the valve, enabling rapid, precise, and remote operation.

This combination of features allows V-port ball valves to be used for applications requiring both throttling and on/off shutoff, offering flexibility in a single device.

V-port ball valves come in several types based on design, actuation, and application:

- Linear V-Port: Provides a straight flow relationship, suitable for simple proportional control.

- Equal-Percentage V-Port: Offers better control for systems where low flow precision is critical.

- Single-acting (spring return): Fails to a default position when air supply is lost.

- Double-acting: Air controls both open and close actions for precise positioning.

- Three-piece: Easy maintenance, removable for inspection.

- Two-piece: Compact design, less maintenance-intensive.

- Top-entry: Allows ball replacement without disconnecting pipeline.

Pneumatic V-port ball valves are versatile, widely adopted in multiple industries:

Used for controlling flow rates of corrosive fluids, acids, and solvents where precision is essential to maintain reaction conditions.

Regulates steam, water, and cooling fluids for turbines, boilers, and heat exchangers.

Maintains sanitary flow control of liquids, syrups, or dairy products. V-port design ensures smooth flow without turbulence that could degrade product quality.

Provides precise control for cleanroom fluid systems, including sterile media and solution distribution.

Controls dosing and distribution of chemicals, such as chlorine, in water treatment plants.

Used for regulating hydrocarbons and natural gas flow in pipelines and refineries with high reliability under pressure.

The combination of V-port design and pneumatic actuation offers multiple benefits:

- Precise Flow Control: V-shaped ball enables accurate throttling over wide flow ranges.

- Fast Actuation: Pneumatic operation ensures rapid response and high cycling capability.

- Automation Integration: Easily connects with PLCs, SCADA, and other process control systems.

- Durability: High-performance materials withstand extreme temperatures, pressures, and corrosive fluids.

- Dual Functionality: Provides both on/off shutoff and proportional flow control in one valve.

- Reduced Process Variability: Stable flow improves product quality and minimizes waste.

When selecting a pneumatic V-port ball valve, several factors must be considered:

- Pressure and Temperature Ratings: Ensure the valve can handle operating conditions.

- Flow Characteristics: Choose linear or equal-percentage V-port based on process control needs.

- Material Selection: Stainless steel, carbon steel, or alloy depending on fluid compatibility.

- Actuator Sizing: Properly sized pneumatic actuator ensures accurate and fast operation.

- Control Systems Integration: Compatibility with positioners, feedback devices, and automation protocols.

Several trends are driving adoption of pneumatic V-port ball valves:

The Industry 4.0 revolution encourages smart, remotely operated valves for process optimization and monitoring.

Complex processes in chemicals, pharmaceuticals, and food production demand high accuracy in fluid handling.

Automated pneumatic valves optimize fluid usage, reducing waste and energy consumption.

Industrial operators prefer V-port ball valves for their low-maintenance design, high durability, and long service life.

Key standards and regulations for pneumatic V-port ball valves include:

- ISO 5211: Standardized actuator mounting.

- ANSI/ASME B16.34: Pressure-temperature ratings for valves.

- API 608: Ball valve design standards.

- CE / ATEX: Safety compliance for European and hazardous environments.

- FDA / 3A Sanitary: For food and pharmaceutical applications.

Compliance ensures reliability, safety, and suitability for industrial environments.

While pneumatic V-port ball valves provide precise flow control, fast actuation, and reliable performance, they are not without operational challenges. Understanding these issues and implementing appropriate solutions is critical for maintaining efficiency, reducing downtime, and prolonging valve lifespan.

Pneumatic actuators rely on clean, dry compressed air. Contaminated or moisture-laden air can lead to actuator corrosion, reduced responsiveness, and premature failure. To mitigate this, operators should install high-quality air dryers, filters, and regulators to ensure consistent air pressure and purity, protecting the actuator and maintaining smooth valve operation.

In processes involving high-velocity fluids or abrasive particles, the V-port edges of the ball can experience wear or erosion over time. This can affect flow accuracy and sealing performance. Using hard-coated, reinforced, or specially alloyed balls designed for abrasive conditions can significantly improve durability and reduce maintenance needs.

Advanced automation and remote operation may require precise calibration of the valve with control systems. Without proper integration, flow performance can become inconsistent. Employing smart positioners and digital feedback systems ensures accurate modulation, seamless communication with PLC or SCADA networks, and optimal process control.

Regular inspection and replacement of seals, seats, and actuators are essential to prevent leaks and maintain valve efficiency. Modular valve designs allow quick replacement of components without removing the valve from the pipeline, minimizing downtime and operational disruption.

By addressing these challenges proactively, pneumatic V-port ball valves can deliver reliable, long-term performance in demanding industrial environments.

A chemical facility replaced standard ball valves with pneumatic V-port ball valves to control reagent dosing. Benefits included improved reaction consistency and reduced process variability.

In a thermal power plant, V-port ball valves controlled boiler feedwater. Rapid pneumatic actuation allowed precise flow adjustments, improving thermal efficiency.

A beverage producer implemented V-port ball valves to manage syrup blending. Automated actuation reduced product loss and improved throughput.

The future of pneumatic V-port ball valves is tied to automation, smart manufacturing, and sustainability:

- Smart Sensors and IoT: Real-time monitoring of flow, pressure, and valve position.

- Predictive Maintenance: Early detection of wear reduces downtime.

- Hybrid Actuators: Combination of pneumatic and electric systems for energy efficiency.

- Expanded Applications: Growth in pharmaceuticals, biotech, and chemical industries will drive demand.

Pneumatic V-port ball valves are a versatile, reliable, and precise solution for controlling flow in industrial processes. Their unique V-port design enables throttling and on/off control in a single device, while pneumatic actuation provides fast, automated operation. Across chemicals, pharmaceuticals, food and beverage, water treatment, and power industries, these valves improve accuracy, safety, efficiency, and automation. With growing trends in smart manufacturing, predictive maintenance, and Industry 4.0 integration, pneumatic V-port ball valves are positioned as a critical component in modern fluid control systems, offering long-term reliability and operational excellence.