The 2-way pneumatic ball control valve is an advanced solution designed to enhance the automation and efficiency of industrial systems. Unlike traditional manually operated valves, the pneumatic version offers significant improvements in ease of operation, reliability, and speed. This ball valve, with its precise control capabilities, is ideal for regulating the flow of liquids and gases in various applications, from manufacturing processes to power generation. The integration of a pneumatic actuator provides seamless automation, reducing human error and enhancing overall system performance.

In this detailed review, we’ll dive into the technical specifications, advantages, and considerations of the 2-way pneumatic ball control valve, providing you with the necessary information to evaluate its suitability for your applications.

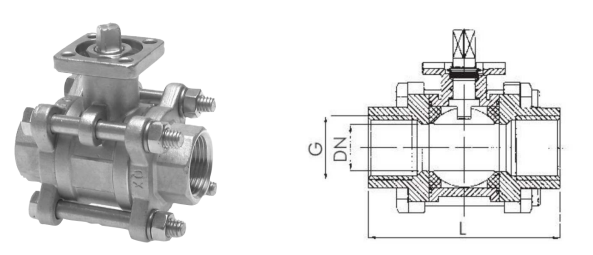

Valve Size and Type: The 2-way ball control valve features a 12 mm diameter, making it suitable for both liquid and gas flow applications.

Temperature Range: The valve is capable of handling a wide temperature range from -20°C to 180°C, ensuring compatibility with a variety of media types and industrial environments.

Pneumatic Actuator Torque: The pneumatic actuator delivers 9.92 Nm of torque at a pressure of 8 bar, offering robust operational performance across a variety of conditions.

Control Pressure Window: For optimal functionality, the actuator operates within a control pressure range of 6 to 10 bar, allowing for smooth and efficient valve control.

Threading: The valve is equipped with G 3/8" threaded connections to easily integrate into existing piping and hosing systems.

Kv Value: With a Kv value of 8.6 m³/h, the valve provides excellent flow capacity, ensuring rapid and reliable media control.

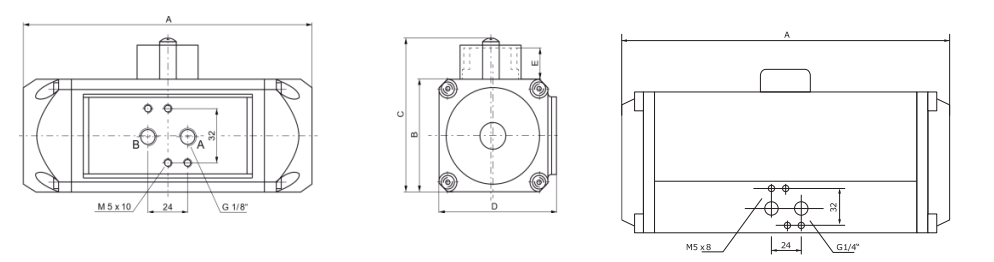

Actuator Type: The actuator is double-acting, providing enhanced control and performance. Its rotational operation is powered by a reliable aluminium rack-and-pinion system.

Actuator Housing: The actuator features a robust anodized aluminum housing for durability, with an acetal resin cover for additional protection and functionality.

Ball Valve Housing: The valve housing is crafted from stainless steel, offering strength and corrosion resistance. It is fitted with a PTFE (Polytetrafluoroethylene) seal to ensure a secure, leak-free connection.

Maximum Media Pressure: The valve is designed to withstand media pressures up to 63 bar, making it suitable for high-pressure applications.

Valve Design: The valve has a 3-piece design, which not only facilitates easier installation but also enables thorough cleaning, ensuring consistent performance over time.

Air Supply and Return Ports: The actuator is equipped with G1/8 ports for air supply and return, allowing for flexible integration into your control system.

Compatibility: A 1/4" Namur solenoid valve can be directly mounted onto the actuator to control the air supply, simplifying the installation process by reducing the number of fittings and tubing required.

Position Control: A position control or limit switch box can be installed on top of the actuator, compliant with VDI/VDE 3845, providing precise feedback and control over the valve’s position.

Mounting Standards: The actuator is mounted to the valve using the ISO 5211 F03 flange (9 mm), ensuring standardized compatibility with various industrial systems.

ATEX Certification: The assembly is ATEX certified (EX II 2GD c), meaning it is safe for use in potentially explosive environments, making it a reliable choice for hazardous applications.

One of the standout features of this valve is its ability to directly mount a Namur solenoid valve. This feature eliminates the need for additional fittings and tubing, streamlining the installation process. By reducing the number of components, the system becomes simpler, more cost-effective, and less prone to leaks or failures.

The valve comes with a mechanical position indicator on top, providing a clear, visual indication of the valve’s current position. This feature is particularly useful in monitoring and troubleshooting, allowing operators to quickly assess the status of the valve without the need for complex instrumentation.

This valve is ATEX (EX II 2GD c) certified, meaning it is approved for use in potentially explosive environments. This certification ensures that the valve operates safely in environments where flammable gases, vapors, or dust may be present, such as in chemical plants or oil and gas facilities.

Compared to electric actuated valves, the pneumatic version offers a more affordable solution, both in terms of initial investment and ongoing maintenance costs. This makes it an attractive choice for applications where budget constraints are a consideration, but reliability and performance are still paramount.

The pneumatic actuator enables rapid opening and closing of the valve, ensuring quick and responsive flow control. This feature is crucial in systems that require fast reaction times, such as in process control or safety applications.

The double-acting actuator provides greater control over the valve’s operation than a single-acting actuator. By utilizing both the supply and exhaust air to control the valve’s motion, it ensures faster and more precise actuation, resulting in smoother and more reliable operation in a variety of applications.

The valve’s 3-piece design makes it easier to disassemble and clean. This feature is especially valuable in applications where hygiene and cleanliness are critical, such as in food processing or pharmaceutical industries. A clean valve also ensures that the system continues to operate efficiently without the buildup of contaminants that could affect performance.

The option to install a limit switch box or position control system offers enhanced monitoring capabilities. This can improve overall system control, making it easier to integrate the valve into automated processes or advanced control systems that require precise position feedback.

While the double-acting actuator provides better control, it also consumes more compressed air than single-acting actuators. This higher energy requirement can lead to increased operating costs in systems that rely heavily on compressed air, particularly in large-scale operations.

Unlike electric actuators, which can operate independently of a compressed air supply, this valve requires a consistent air supply and a solenoid valve to control it. This introduces additional infrastructure needs, such as the need for air compressors and maintenance of the air system.

Pneumatic actuators generally consume more energy than their electric counterparts, as they rely on compressed air to operate. While the initial investment for a pneumatic system is typically lower, the ongoing energy costs may be higher over time, especially if the valve is in frequent operation.

The 2-way pneumatic ball control valve is ideal for a range of industrial applications, particularly in systems that require rapid, automated flow control. Some common use cases include:

The valve’s fast opening and closing capabilities make it an excellent choice for regulating the flow of liquids and gases in processing plants.

With its ATEX certification, this valve is well-suited for use in hazardous environments, such as those found in chemical processing or oil and gas facilities.

The valve is effective in controlling water flow in municipal or industrial water treatment systems, where precise regulation and reliable operation are essential.

Its 3-piece design allows for easy cleaning, making it an ideal choice for applications in the food and beverage sector, where hygiene is a priority.

The valve’s reliability, ease of maintenance, and compliance with industry standards make it suitable for pharmaceutical manufacturing processes that require strict control over fluid and gas handling.

The 2-way pneumatic ball control valve is a versatile and reliable solution for a wide range of industrial applications. Its pneumatic actuation provides faster, more precise control than manual valves, and its ability to integrate seamlessly with automated systems makes it a cost-effective choice for enhancing process efficiency. With its robust design, ATEX certification, and the option for position control, this valve is a great option for industries that demand safety, reliability, and high performance.

While the pneumatic system does require a compressed air supply and may have higher energy consumption compared to electric actuators, its lower initial cost and faster operation make it an attractive choice for many applications. By considering both the benefits and potential drawbacks, you can determine whether the 2-way pneumatic ball control valve is the right solution for your specific needs.