On this page

Control valve actuators are essential components in industrial systems, providing the force necessary to move and control valves for precise flow, pressure, or temperature regulation. Actuators come in various types, but this discussion focuses on two primary categories: pneumatic actuators and electric actuators, which are widely used across different applications.

Pneumatic actuators rely on compressed air to generate the force required for valve operation. They are known for their reliability, speed, and ability to operate in hazardous environments where electric actuators might pose risks. Pneumatic actuators are particularly effective for controlling valves in demanding industrial settings.

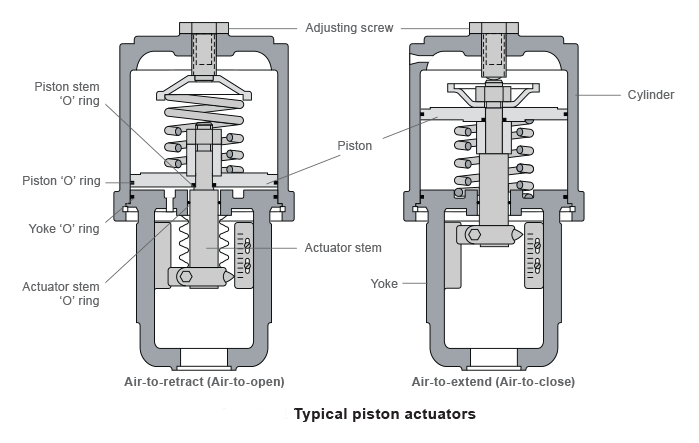

These actuators use a piston and cylinder arrangement to convert air pressure into mechanical motion.

They are suitable for applications requiring high force output and a long stroke.

They are ideal for lower-pressure applications and provide precise control for throttling. In reverse-acting actuators, the spring extends the actuator stem when air pressure is released.

Commonly used in fail-safe applications where valves need to close during power or pressure loss. Direct-acting actuators retract the stem when air pressure is removed.

They are used for applications requiring a fail-open response during pressure failure. Valve positioners enhance the accuracy and performance of pneumatic actuators. These devices adjust the actuator’s air pressure to maintain the desired valve position in response to input signals. Positioners also:

Compensate for external factors like friction to minimize hysteresis (lag in response).

Allow for increased spring range to enhance closing force, enabling the valve to handle higher differential pressures.

For example, in an air-to-open valve and actuator system, the positioner adjusts air pressure to ensure the valve opens fully, overcoming friction and other resistance. Electric actuators use electrical energy to create motion, either rotary or linear, to control valves. These actuators are valued for their precision, easy integration into automated systems, and ability to operate without compressed air systems.

They are suitable for applications requiring high force output and a long stroke.

They are ideal for lower-pressure applications and provide precise control for throttling. In reverse-acting actuators, the spring extends the actuator stem when air pressure is released.

Commonly used in fail-safe applications where valves need to close during power or pressure loss. Direct-acting actuators retract the stem when air pressure is removed.

They are used for applications requiring a fail-open response during pressure failure. Valve positioners enhance the accuracy and performance of pneumatic actuators. These devices adjust the actuator’s air pressure to maintain the desired valve position in response to input signals. Positioners also:

Compensate for external factors like friction to minimize hysteresis (lag in response).

Allow for increased spring range to enhance closing force, enabling the valve to handle higher differential pressures.

For example, in an air-to-open valve and actuator system, the positioner adjusts air pressure to ensure the valve opens fully, overcoming friction and other resistance. Electric actuators use electrical energy to create motion, either rotary or linear, to control valves. These actuators are valued for their precision, easy integration into automated systems, and ability to operate without compressed air systems.

Electric actuators provide fine control over valve position, making them ideal for applications demanding accuracy.

Easily integrated into modern control systems via digital communication protocols like Modbus or Profibus.

They do not require air compressors, reducing energy consumption and maintenance costs.

Operate on various voltage levels, catering to different industrial setups.

Electric actuators are commonly used in settings where precise control is critical, such as:

Water and wastewater treatment.

HVAC systems.

Chemical processing.

Oil and gas industries.

Selecting the right actuator depends on several factors:

Water and wastewater treatment.

HVAC systems.

Chemical processing.

Oil and gas industries.

|

Feature |

Pneumatic Actuators |

Electric Actuators |

|

Power Source |

Compressed air |

Electrical energy |

|

Control Precision |

Moderate |

High |

|

Speed |

Fast |

Moderate |

|

Maintenance |

Requires air system maintenance |

Low maintenance requirements |

|

Hazardous Environments |

Suitable due to no electrical components |

May require additional safety precautions |

|

Energy Efficiency |

Relatively low (requires compressors) |

Higher energy efficiency |

Determine if high-speed operation (pneumatic) or high precision (electric) is more important.

For explosive or hazardous environments, pneumatic actuators are generally safer.

Consider the availability of compressed air or electrical power.

Factor in the initial investment and long-term maintenance costs.

Control valve actuators are indispensable in modern industrial systems, enabling precise and reliable control of processes. Pneumatic actuators excel in speed and reliability under harsh conditions, while electric actuators offer precision and energy efficiency. By understanding the unique advantages of each type and integrating tools like valve positioners, operators can optimize performance to meet specific application requirements.