In the world of industrial flow control, the eccentric plug control valve stands out as a versatile and reliable solution for handling challenging media such as slurries, grit, and solids. Combining the ruggedness and durability of globe valves with the simplicity and precision of rotary control valves, eccentric plug valves have become a preferred choice for industries requiring high control accuracy and wide rangeability. This article delves into the design, functionality, applications, and performance characteristics of eccentric plug control valves, providing a detailed understanding of their role in modern flow control systems.

An eccentric plug control valve is a type of rotary control valve that features a uniquely shaped plug designed to handle demanding flow conditions. Unlike traditional valves, the plug in an eccentric plug valve does not come into contact with the valve seat until it is within a few degrees of the closed position. This design minimizes wear and tear on the sealing surfaces, ensuring reliable shut-off and extended valve life.

The plug, often referred to as a "cam," follows an eccentric path as it rotates. When the valve approaches the closed position, the plug dynamically aligns with the seat, creating a tight seal. This innovative design makes eccentric plug valves particularly effective for applications involving abrasive or viscous media.

Eccentric plug control valves typically feature a one-piece body construction, which enhances durability and reduces the risk of leakage. The body is available in flanged (ASME Class 150/PN25) or wafer-type configurations, making it suitable for a wide range of piping systems.

The eccentric plug is the defining feature of this valve. Its unique shape and rotational path allow it to avoid contact with the seat until the final moments of closure. This reduces friction and wear, ensuring long-term performance and reliability.

The sealing surfaces of the plug and seat are dynamically aligned during closure, ensuring a tight shut-off even in the presence of solids or abrasive particles. This makes eccentric plug valves ideal for applications where traditional valves might fail.

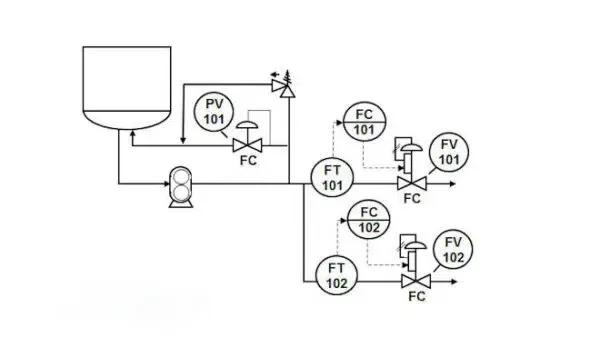

Eccentric plug control valves are typically equipped with pneumatic actuators, digital or smart positioners, and air filter regulators. These components work together to provide precise flow control and automation capabilities.

Eccentric plug control valves are widely used in industries that require robust and reliable flow control solutions. Some of the most common applications include:

The ability to handle abrasive and viscous media makes eccentric plug valves ideal for slurry applications in industries such as mining, wastewater treatment, and chemical processing.

In industries like food processing, pulp and paper, and pharmaceuticals, eccentric plug valves are used to control the flow of media containing solids or particulate matter.

High-Pressure and High-Temperature Applications

The rugged design of eccentric plug valves makes them suitable for high-pressure and high-temperature environments, such as those found in power generation and oil and gas industries.

Eccentric plug valves are often constructed from materials resistant to corrosion, making them suitable for use with aggressive chemicals and acids.

Eccentric plug valves offer precise flow control, making them suitable for applications where accuracy is critical.

These valves provide excellent rangeability, allowing them to perform effectively across a wide range of flow rates.

The eccentric plug design minimizes wear and tear, resulting in a longer service life compared to traditional valves.

The robust construction and innovative design of eccentric plug valves reduce the need for frequent maintenance, lowering operational costs.

Eccentric plug valves can handle a variety of media, including slurries, solids, and corrosive substances, making them suitable for diverse industrial applications.

The flow curve of a control valve represents the relationship between the valve's opening position and the flow rate through the valve. For eccentric plug control valves, the flow curve is typically characterized by the following features:

In many cases, eccentric plug valves exhibit a linear flow characteristic, meaning that the flow rate increases proportionally with the valve opening. This makes them easy to control and ideal for applications requiring precise flow regulation.

Some eccentric plug valves are designed with equal percentage flow characteristics, where the flow rate increases exponentially with the valve opening. This type of flow curve is beneficial in applications where fine control is required at low flow rates.

In certain configurations, eccentric plug valves may exhibit quick opening flow characteristics, where a small change in valve position results in a significant increase in flow rate. This is useful in applications requiring rapid response.

Choosing the right eccentric plug control valve for your application involves considering several factors:

Determine the nature of the media being handled, including its viscosity, abrasiveness, and corrosiveness. This will help you select a valve with the appropriate materials and design features.

Consider the required flow rate, pressure, and temperature conditions. Ensure that the valve's flow characteristics align with your system's needs.

Select a valve size and connection type (flanged or wafer) that matches your piping system. Ensure that the valve can be easily integrated into your existing infrastructure.

Choose an actuation method (pneumatic, electric, or hydraulic) and control system (manual, digital, or smart) that meets your operational requirements.

Consider the availability of spare parts, maintenance requirements, and manufacturer support when selecting a valve.

Eccentric plug control valves represent a significant advancement in flow control technology, offering a unique combination of durability, precision, and versatility. Their ability to handle challenging media, such as slurries and solids, makes them indispensable in a wide range of industrial applications. By understanding the design, functionality, and performance characteristics of eccentric plug valves, operators can make informed decisions when selecting and implementing these valves in their systems. As industries continue to evolve, eccentric plug control valves will remain a critical component in achieving efficient and reliable flow control.