Selecting the right control valve for a process system is essential to achieving efficiency, reliability, and safety—but an often-overlooked element in this selection process is the valve bonnet. While the body and trim tend to get all the attention, the bonnet plays an equally crucial role in the performance, durability, and maintainability of the valve. Choosing the appropriate bonnet type can mean the difference between smooth, leak-free operation and costly maintenance issues down the line.

In this article, we’ll dive into what a control valve bonnet is, explore its functions, and take a close look at the most common bonnet types, when to use them, and how to match the right one to your unique operating conditions.

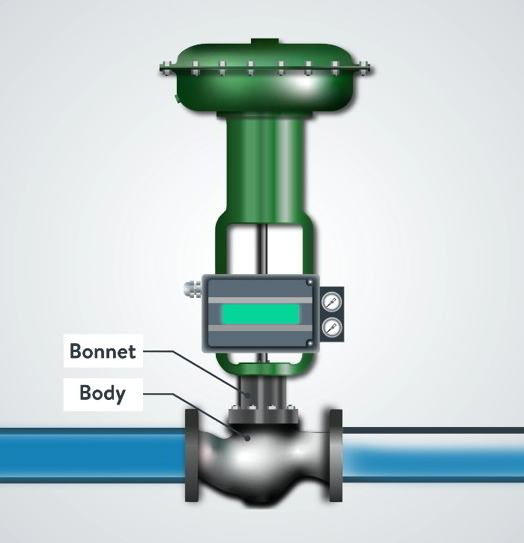

A control valve bonnet is essentially the closure component that covers the top opening of the valve body. Think of it as the valve’s protective cap and gateway—it seals the valve internals against external conditions, supports the stem and packing, and creates a robust interface with the actuator. Its design ensures that the internal parts, such as the stem, packing, and actuator connections, are not exposed to harmful environmental conditions or process media leaks.

The bonnet may seem like a simple cover, but its design and material selection must match the valve’s service requirements. An incorrect bonnet type can lead to packing failures, stem damage, leaks, or even hazardous fluid emissions.

To appreciate why bonnet selection is so important, it helps to understand the critical roles bonnets play in valve operation:

The bonnet shields delicate internal parts like the stem, packing, and actuator connection from external elements such as dust, moisture, corrosive environments, or mechanical impacts. This protection extends the life of the valve and reduces unplanned downtime.

A major function of the bonnet is to maintain a reliable, leak-tight seal between the valve body and its internal components. This prevents process media from escaping into the atmosphere or external contaminants from entering the valve.

In extreme temperature applications—whether cryogenic service or high-temperature steam—the bonnet design often includes features to insulate or extend the stem and packing away from the harsh process fluid, preserving the integrity of seals and moving parts.

Bonnets are designed to allow relatively easy access to internal components during maintenance or inspection. The right bonnet type helps maintenance teams replace packing, inspect the stem, or perform repairs without extensive disassembly.

Positioned between the valve body and actuator, the bonnet forms a critical structural link and sealing surface. The choice of bonnet type directly affects the valve’s pressure rating, temperature capability, leakage class, and overall safety performance.

Since industrial process conditions vary widely, valve bonnets are designed in several configurations, each addressing specific service demands. Let’s examine the five most common types and how to select the best fit for your application.

Overview:

The standard bonnet is the workhorse design used in the majority of general-purpose control valves. It’s engineered for moderate temperature and pressure conditions where no special thermal or sealing considerations are required.

Recommended Temperature Range:

Typically suitable for process fluids with temperatures ranging from -20°C to +230°C (-4°F to +450°F).

Typical Applications:

Water treatment plants

General fluid distribution networks

Heating and cooling systems

Non-hazardous chemical processes

Advantages:

Cost-effective and simple design

Easy to maintain

Compatible with a broad range of standard actuators and packing materials

Selection Tip:

A standard bonnet is your go-to option if your process conditions do not involve extreme temperatures, pressures, or hazardous media. Be sure to verify that the chosen valve materials are compatible with your fluid characteristics.

Overview:

When processes involve fluids at very high or very low temperatures, standard bonnets can lead to rapid packing wear or failure. Extension bonnets solve this by creating a thermal barrier—extending the stem and packing area away from the extreme temperatures of the process media.

How it Works:

An extension bonnet includes a lengthened stem housing that acts as an insulating chamber. For high-temperature services, it keeps the packing cooler than the fluid; for cryogenic services, it prevents cold fluids from freezing the packing.

Recommended Temperature Range:

From as low as -60°C (-76°F) for cryogenic services to as high as +450°C (+842°F) for superheated steam or thermal oil systems.

Typical Applications:

LNG terminals

Cryogenic storage and transport systems

Steam distribution networks

High-temperature chemical processes

Advantages:

Extends packing and stem life in thermal extremes

Reduces maintenance frequency

Improves valve reliability in challenging temperature zones

Selection Tip:

Always confirm the length of the extension is suitable for the temperature gradient. In cryogenic service, industry standards like ANSI/ISA often dictate minimum stem lengths for safe operation.

Overview:

Where leakage control is absolutely critical—whether for toxic, radioactive, corrosive, or very expensive fluids—a bellows seal bonnet provides an additional layer of protection. This design includes a flexible metal bellows welded to the stem and bonnet, forming a hermetic seal that isolates the packing from the process fluid.

How it Works:

The bellows expands and contracts with stem movement, preventing process fluid from reaching the packing area. This means even if the packing were to fail, the bellows would still contain the fluid, dramatically reducing fugitive emissions.

Use Cases:

Handling highly toxic or carcinogenic chemicals

Radioactive fluid containment in nuclear plants

Applications with very expensive process media, where every drop counts

Pharmaceutical or semiconductor manufacturing, where purity is vital

Advantages:

Exceptional leak-tight performance

Meets stringent environmental and safety regulations

Extends packing life by isolating it from the process fluid

Selection Tip:

Always check the bellows cycle life specification. Frequent valve cycling can fatigue the bellows over time, so for high-cycle applications, ensure the bellows is rated for your operating frequency.

Overview:

Some process fluids tend to solidify, become highly viscous, or form deposits when cooled to ambient temperatures. A jacketed bonnet helps maintain the fluid at the desired temperature by allowing external heating or cooling media to circulate around the valve’s bonnet and body.

How it Works:

Hot oil, steam, or another heat transfer fluid flows through the jacket cavity, maintaining process fluid flowability. This prevents clogging and ensures consistent valve performance.

Typical Applications:

Bitumen, asphalt, or heavy crude oil pipelines

Food and beverage processing (chocolate, syrups)

Polymer or resin production

Any process with temperature-sensitive, viscous, or easily solidified media

Advantages:

Maintains optimal process fluid characteristics

Prevents blockages that could damage the valve or piping

Reduces downtime caused by cleaning or thawing frozen lines

Selection Tip:

Ensure the jacket covers all sections where fluid could stagnate and solidify. Partial jacketing may leave cold spots, defeating the purpose.

Overview:

In high-pressure, high-temperature applications, gasketed bolted bonnets may struggle to maintain a tight seal due to thermal expansion and internal pressure. A pressure seal bonnet solves this by using system pressure to enhance sealing.

How it Works:

The bonnet design uses the system’s internal pressure to force a seal ring or gasket tighter against the valve body. The higher the internal pressure, the tighter the seal—making it ideal for steam systems and other high-pressure services.

Typical Applications:

Power generation plants (boilers, steam turbines)

Petrochemical refineries

High-pressure water or gas transmission systems

Advantages:

Superior leak-tightness under high-pressure conditions

Self-energizing design reduces bolting requirements

Compact construction for easier installation in high-pressure piping systems

Selection Tip:

Proper installation is critical—incorrect seating of the pressure seal ring can lead to leaks or damage under high loads. Always follow the manufacturer’s assembly guidelines.

When selecting a control valve bonnet, remember that there is no universal solution. Consider these key factors during your evaluation:

Match the bonnet type to the expected operating range to prevent packing damage and leaks.

Is the fluid toxic, corrosive, radioactive, or viscous? This will determine whether you need specialized containment or temperature control.

Many industries, such as nuclear or pharmaceutical, have strict requirements for fugitive emissions and leak prevention.

A well-chosen bonnet design can reduce maintenance intervals and costs by protecting critical components and simplifying access.

For high-cycle operations, choose bonnets and sealing systems with sufficient durability to handle repeated stem movement without fatigue.

While specialized bonnets come at a higher upfront cost, they often pay for themselves through reduced downtime, improved safety, and compliance with environmental regulations.

A control valve is only as good as its weakest link—and the bonnet is far from a trivial component. It plays a pivotal role in sealing performance, stem protection, temperature management, and leak prevention. By understanding the unique demands of your process and the characteristics of each bonnet type, you can make informed choices that improve reliability, extend valve life, and protect both your people and the environment.

Next time you’re specifying a control valve, give the bonnet the attention it deserves—it’s a small investment in the grand scheme of your system, but one that can deliver significant returns in safety, performance, and peace of mind.