In today’s industrial landscape, efficiency, safety, and reliability are non-negotiable. For processes that demand precise isolation and full-flow capabilities, multi-turn electric gate valves have become a trusted solution. These electrically actuated valves are designed for fully open or fully closed operation, ensuring unrestricted flow paths when required and tight shut-off when needed.

Multi-turn electric gate valves stand out for their robust construction, high flow rates, and remote control capabilities. They are widely used across diverse sectors such as pulp and paper, power generation, mining, petrochemical plants, wastewater treatment facilities, and iron and steel production. Available in multiple international standards including ANSI, JIS, DIN, and GB, these valves can be tailored to meet different regional and application-specific requirements.

Additionally, electric knife gate valves — ideal for handling slurry, pulp stock, or abrasive media — provide another reliable option for industries with demanding flow control needs. As an experienced electric actuator valve manufacturer, we provide comprehensive solutions that cover ball valves, butterfly valves, gate valves, and globe valves, all integrated with high-performance electric actuators to meet your project’s exact needs.

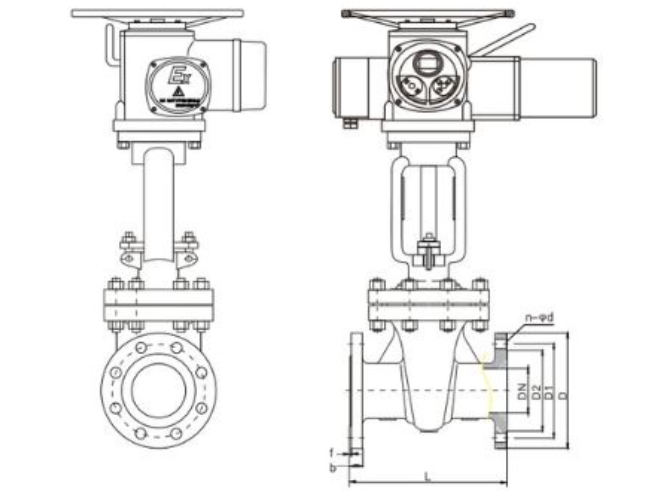

A multi-turn electric gate valve is an isolation valve operated by an electric actuator that converts electrical energy into mechanical rotational motion. This motion, in turn, drives the stem and gate to move linearly, either lifting the gate clear of the flow path (fully open) or lowering it to block the passage (fully closed). The “multi-turn” designation refers to the actuator’s need to rotate multiple times to achieve full open or close positions — a critical factor for handling large-diameter pipelines and high-pressure systems.

Unlike manual gate valves, these valves can be operated remotely through control systems, distributed control systems (DCS), or supervisory control and data acquisition (SCADA) interfaces. This not only enhances operational efficiency but also improves safety by minimizing the need for manual intervention in hazardous or hard-to-reach locations.

Whether in a power station’s cooling water circuit, a chemical plant’s process lines, or a pulp mill’s slurry transfer system, the multi-turn electric gate valve provides dependable shut-off and isolation, minimizing downtime and maximizing productivity.

Modern multi-turn electric gate valves come equipped with an array of performance-enhancing features that make them a valuable addition to any flow control system:

Actuators are available with torque outputs ranging from as low as 50 Nm up to 10,000 Nm or more, enabling operators to handle small to large-diameter pipelines with ease.

Options include three-phase AC, single-phase AC, or DC motors, allowing integration with various power supply setups.

Valves can be supplied according to ANSI, JIS, DIN, and GB standards to align with regional codes and customer specifications.

A robust sealing design minimizes leakage, ensuring low fluid resistance and a tight shut-off for critical isolation tasks.

Gate sealing surfaces are typically made from stainless steel or hard alloys, providing corrosion resistance, erosion protection, and extended durability, even in aggressive media.

The design supports flow in either direction, enhancing system design flexibility.

Available with Profibus, Modbus, Hart, or other fieldbus protocols, the valves can be integrated seamlessly into modern smart plant architectures, supporting predictive maintenance and remote diagnostics.

Choose from carbon steel (WCB), stainless steel, or cast iron bodies, depending on your application’s pressure class, media type, and environmental conditions.

Depending on installation requirements and space constraints, multi-turn electric gate valves come in several configurations:

In rising stem gate valves, the stem moves up or down as the valve opens or closes. This visible movement provides a clear and immediate visual indicator of the valve’s status, which is especially beneficial for plant operators conducting inspections. They are widely used in applications where there is sufficient vertical space.

For tight or buried installations, non-rising stem gate valves are ideal. Here, the stem remains stationary in its vertical position while a threaded portion inside the valve body operates the gate. These are common in underground pipelines, shipyards, and space-constrained industrial plants.

Knife gate valves are specialized gate valves with a sharp-edged gate that can cut through thick media like pulp stock, slurry, or viscous fluids. When fitted with a multi-turn electric actuator, these valves offer powerful remote-controlled shut-off capabilities for challenging flow streams.

At the heart of a multi-turn electric gate valve is its actuator. The actuator receives electrical power and converts it into rotational torque through a motor. This rotational torque is then transferred to the valve’s stem via gear mechanisms. The stem, in turn, translates this rotary motion into a linear motion, raising or lowering the gate inside the valve body.

Modern electric actuators feature integrated position feedback, torque limiters, and fail-safe functions to prevent over-torquing, jamming, or damage due to unexpected flow conditions. Many models include local and remote control switches, position indicators, and digital communication interfaces for smooth integration into plant automation systems.

The versatility of multi-turn electric gate valves makes them an integral part of many industrial sectors:

Used for steam, condensate, cooling water, and fuel lines, ensuring safe isolation during maintenance or emergencies.

Knife gate valves, in particular, excel at handling slurry and pulp stock with high solid content.

Ideal for onshore and offshore pipelines, storage terminals, and refinery units.

Handle abrasive slurries, tailings, and process fluids reliably.

Automate large-diameter intake or discharge lines, improving safety and efficiency.

Control process water, cooling circuits, and raw material pipelines.

Isolate corrosive or hazardous chemicals with robust sealing materials and corrosion-resistant bodies.

With the rise of Industry 4.0 and smart plant operations, electric actuators can be equipped with digital fieldbus modules. Options like Profibus DP, Modbus RTU, Hart, DeviceNet, and Foundation Fieldbus allow seamless communication with distributed control systems.

These advanced features enable real-time monitoring of valve status, torque levels, cycle counts, and predictive maintenance data. Plant operators can receive alerts for unusual torque spikes, partial closures, or motor overheating — minimizing unplanned downtime and optimizing maintenance schedules.

Unlike manual gate valves that require significant physical effort to operate large diameters, multi-turn electric gate valves drastically reduce operator fatigue and risk exposure. By automating isolation tasks, personnel can control valves from a safe distance, avoiding hazardous zones.

Routine maintenance for electric gate valves focuses primarily on ensuring actuator integrity, verifying position switches, and checking for wear on the sealing surfaces. Many modern actuators are designed for easy access and modular repair, ensuring minimal process interruption.

Choosing the best multi-turn electric gate valve for your application involves evaluating several factors:

Ensure the actuator torque range matches the valve’s operational requirements.

For slurries and thick fluids, knife gate valves with hardened edges are ideal.

Confirm compatibility with your facility’s communication protocols.

Consider corrosion-resistant materials for marine, chemical, or high-humidity environments.

Verify that the valve meets ANSI, JIS, DIN, or GB standards relevant to your region and industry.

As industries push toward greater automation and smarter control systems, working with an experienced valve manufacturer ensures you get a solution that balances performance, durability, and cost-effectiveness. Our multi-turn electric gate valves are engineered with the highest standards of quality and backed by decades of expertise.

From project consultation and design customization to fabrication and after-sales support, we are committed to delivering valves that keep your operations running safely and efficiently. Our complete product portfolio includes not only electric gate valves but also ball valves, butterfly valves, and globe valves with reliable electric actuators — all available in custom materials and sizes to suit your specific project.

The multi-turn electric gate valve is more than just a flow control device; it is a vital element of industrial automation that provides safe, efficient, and reliable isolation of critical process lines. Whether your project demands standard shut-off valves or specialized knife gate designs, integrating an electric actuator will help streamline operations, enhance safety, and support the journey towards smarter, more sustainable facilities.

Looking to upgrade your valve systems or need advice on the best solution for your application? Contact our team today for expert guidance and a competitive quote tailored to your needs.