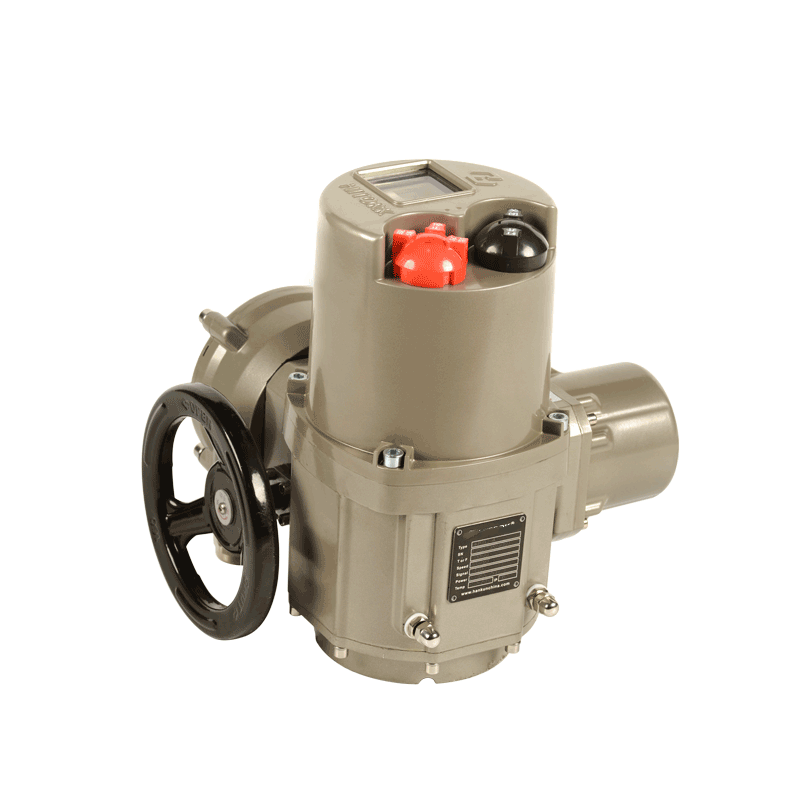

Quarter-turn electric actuators are indispensable in industrial automation, designed to streamline and enhance the efficiency of processes involving valves and dampers. These devices use electrical energy to execute precise operations such as opening, closing, and throttling. Their ability to perform a 90° rotary motion makes them suitable for applications with valves like ball valves, plug valves, choke valves, dump valves, and butterfly valves. They are equally valuable in automating dampers for regulating airflow in chimneys and HVAC systems.

In this article, we’ll delve into the operational features, potential issues, and troubleshooting techniques to ensure optimal performance of quarter-turn electric actuators.

Quarter-turn electric actuators automate valves that operate through a 90° rotary motion. These actuators are equipped with electric motors (either AC or DC) and robust mechanical and electronic components to deliver accurate positioning. They are especially beneficial in applications where precision, reliability, and efficiency are essential.

Quarter-turn electric actuators offer several advantages:

These actuators are lightweight and occupy minimal space, making them ideal for installations where space is constrained.

They eliminate the need for pneumatic systems, reducing operational and maintenance costs.

Designed to use electrical energy effectively, they reduce overall energy consumption.

Capable of handling a broad range of torque requirements, they are suitable for diverse industrial applications.

Quarter-turn electric actuators are engineered for durability and high performance. Below are some standout features that ensure reliability even in demanding environments:

Specially hobbed for reduced wear, these gears enhance longevity and operational efficiency.

Ensures consistent performance by eliminating the need for frequent lubrication and reducing maintenance efforts.

Calibrated separately for open and closed positions, these switches provide precise control over valve movements.

Specifically designed for efficient bidirectional motion, critical for valve and damper automation.

Polyester powder coatings provide excellent resistance against UV degradation, aggressive corrosion, and environmental wear.

Numbered terminal strips streamline field wiring, making installation and maintenance more convenient.

Safeguards the motor from overheating, enhancing the safety and longevity of the actuator.

Despite their robust design, quarter-turn electric actuators can encounter issues over time, primarily due to wear, environmental factors, or improper handling. Here are some common problems:

Overheating, electrical faults, or prolonged wear can lead to motor malfunction.

Misalignment, corrosion, or physical damage to the limit switches can cause inaccurate valve positioning.

Mechanical wear or damage can impede the actuator’s performance or cause complete failure.

Faulty wiring or damaged circuit boards can disrupt the actuator’s operation.

Exposure to extreme temperatures, moisture, or corrosive substances can compromise actuator functionality.

To ensure optimal performance, addressing issues promptly is crucial. Below are comprehensive troubleshooting steps to help identify and resolve problems with quarter-turn electric actuators:

Check whether the actuator is receiving the correct voltage as per its specifications.

Inspect for blown fuses, tripped breakers, or any interruptions in the power supply.

Examine the motor for signs of overheating, unusual noises, or physical wear.

Test the motor’s electrical connections and confirm that it is receiving appropriate input signals.

Ensure that the limit switches are properly aligned and functioning correctly.

Misaligned or damaged switches can lead to improper valve operation or failure to stop at designated positions.

Inspect the gearbox for wear, leaks, or any physical damage.

Verify that the gears are adequately lubricated and free from excessive resistance or play.

Check the valve stem for obstructions, corrosion, or mechanical damage that might impede movement.

Ensure proper alignment between the stem and the actuator to avoid unnecessary stress.

Confirm that all wiring connections are secure and free from corrosion or damage.

Test circuit boards, relays, and other electrical components to ensure proper functionality.

Use diagnostic tools to check if the actuator is receiving and responding to control signals accurately.

Assess whether the actuator is exposed to conditions like moisture, dust, or extreme temperatures that may cause damage.

Consider using protective enclosures or coatings to mitigate environmental impact.

To avoid frequent issues and prolong the lifespan of your actuator, regular maintenance is essential. Below are some maintenance tips:

Schedule regular checks to identify and address potential issues early.

Ensure that all moving parts are adequately lubricated to prevent wear and tear.

Protect the actuator from exposure to harsh environmental conditions by using enclosures or specialized coatings.

Periodically recalibrate the limit switches and test the actuator to maintain precision.

Remove dust, debris, and contaminants from the actuator’s surfaces and electrical connections.

Keep track of the actuator’s performance metrics to detect anomalies that may indicate potential issues.

Implementing proactive troubleshooting and maintenance measures offers several benefits, including:

Prompt resolution of issues minimizes operational disruptions.

Preventative maintenance reduces the need for expensive repairs or replacements.

Regular checks ensure consistent performance, improving process reliability.

Proper care and timely interventions can significantly extend the life of the actuator.

Well-maintained actuators operate more efficiently, reducing energy consumption and improving productivity.

Quarter-turn electric actuators are used in various industries due to their versatility and precision. Some common applications include:

Automating valves for flow control and safety systems.

Ensuring precise control of aggressive or hazardous media.

Regulating airflow in chimneys, ducts, and air-handling units.

Managing water flow in filtration and distribution systems.

Maintaining hygiene standards by automating valves in clean environments.

Quarter-turn electric actuators are critical components for automating valves and dampers, delivering precise control in various industrial applications. Understanding their features, addressing common issues, and implementing effective troubleshooting steps are essential for maintaining their performance and reliability.

Regular maintenance and proactive care not only minimize downtime but also enhance the overall efficiency of industrial processes. By following the outlined troubleshooting techniques and preventative measures, operators can ensure that their quarter-turn electric actuators remain in optimal working condition, contributing to the success of their operations.

Investing in high-quality actuators and adopting a diligent maintenance routine is a wise decision that pays off in terms of reliability, efficiency, and long-term savings.