In industrial applications where flow control is critical, precision, reliability, and efficiency are paramount. V-Port Ball Control Valves, commonly known as V-Ball Valves, have become a top choice due to their ability to offer superior flow regulation and high performance in a wide range of environments. Combining the robust sealing characteristics of traditional ball valves with the precise flow control of specialized control valves, V-Port Ball Valves are engineered to meet the stringent demands of industries where accurate temperature control, pressure management, and flow regulation are essential. This article provides an in-depth look at the design, materials, key applications, and benefits of V-Port Ball Control Valves, underscoring their importance in optimizing industrial processes.

V-Port Ball Control Valves are distinguished by their unique V-shaped port design, which enhances the valve’s ability to provide precise flow modulation. Unlike traditional ball valves, which offer a simple on/off function, V-Port valves incorporate a flow-modulating element that can precisely regulate fluid flow at various stages. These valves come in several standard configurations, including 15°, 30°, 60°, and 90° angles. Additionally, manufacturers can customize the port geometry with slotted or tailored V-Port designs to meet specific operational requirements, allowing for optimal flow control in a variety of applications.

The construction of V-Port Ball Control Valves includes high-quality materials such as 316 stainless steel (CF8M) and carbon steel (WCB), both of which offer exceptional durability, corrosion resistance, and strength. These materials ensure the valves can withstand the harshest environments, including extreme temperatures, steam systems, and chemically aggressive applications. With robust body and ball configurations, V-Port Ball Control Valves are highly reliable, even in demanding situations that may involve high-pressure or abrasive media.

V-Port Ball Control Valves are designed to excel across a wide spectrum of industrial applications, offering highly specialized benefits for several key sectors:

The precision flow modulation offered by V-Port valves is ideal for regulating temperature in systems where maintaining stable conditions is crucial. In HVAC systems and industrial heating processes, V-Port valves are used to provide accurate temperature regulation, ensuring efficient energy use and consistent performance.

These valves are widely used in industries that require consistent and precise control over fluid flow, such as in water treatment plants and chemical processing facilities. The V-Port’s high rangeability and customizable geometry enable these valves to manage both high and low flow rates effectively, optimizing process control and enhancing operational efficiency.

Steam systems often operate under extreme conditions where valve reliability is essential. V-Port Ball Control Valves, with their robust construction and tight shut-off capabilities, are particularly effective in controlling steam flows, ensuring stable and efficient operation in high-temperature and high-pressure environments.

Cavitation, which occurs when pressure in the valve drops too quickly, can cause significant damage to valves and other components in fluid control systems. V-Port valves help mitigate cavitation by offering smooth flow regulation, minimizing the risk of valve damage and improving system efficiency.

V-Port valves also find extensive use in level control and pH regulation, particularly in wastewater treatment and pharmaceutical manufacturing. Their precise control capabilities help ensure that processes are maintained within required thresholds, contributing to product consistency and environmental safety.

V-Port Ball Control Valves offer several distinct features and benefits that make them a standout choice for industries requiring advanced flow control:

V-Port valves provide Class VI bubble-tight shut-off, preventing fluid leakage and ensuring that process fluids remain contained. This feature is especially crucial in applications where hazardous or expensive fluids are involved, as it reduces waste and prevents safety risks.

The V-shaped port geometry allows for a wide range of flow control, making V-Port Ball Valves versatile in applications that demand precise adjustments from low to high flow rates. This ability to handle varying flow conditions ensures optimal performance across diverse industrial systems.

The streamlined flow path of the V-Port design minimizes pressure drop across the valve, reducing energy consumption and improving overall system efficiency. This feature is especially beneficial in large-scale operations where energy savings translate into significant cost reductions.

The quarter-turn operation of the V-Port Ball Control Valve provides fast response times, which is crucial in applications that require quick adjustments to maintain stable system conditions. This capability ensures that processes run smoothly with minimal delays.

V-Port Ball Control Valves are designed to be compact and lightweight, making them easy to install and integrate into existing systems. Their compact nature reduces the need for large valve chambers, saving space and simplifying system layout.

The ability to customize the V-Port geometry means these valves can be tailored to meet the specific needs of each application. Whether it's for specialized flow regulation or unique process conditions, V-Port Ball Valves can be engineered to deliver optimal performance.

V-Port valves are designed to meet a wide range of international standards, including API 607, ATEX, NACE MR0175, PED, PE(S)R, SIL, and TR CU. This ensures that they comply with global regulatory requirements and guarantees their reliability and durability in even the most demanding applications.

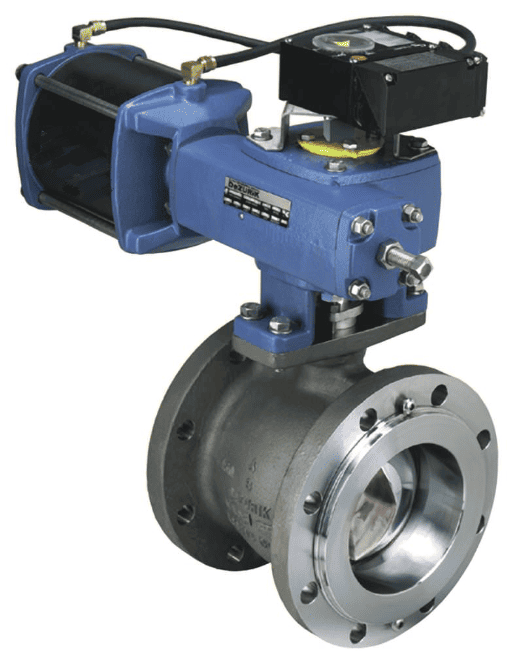

For maximum performance, V-Port Ball Control Valves can be integrated with advanced actuators and control systems. By pairing these valves with high-quality pneumatic, electric, or electro-hydraulic actuators, and precision controllers, industries can enhance the valves’ rangeability, repeatability, and overall control accuracy. This integration offers an added layer of reliability and ensures smooth, automated operation across industrial control systems, improving both performance and efficiency.

V-Port Ball Control Valves represent a major leap forward in flow control technology, offering a remarkable blend of precision, versatility, and reliability. With their ability to deliver zero leakage, high rangeability, and quick response times, these valves are invaluable assets in a variety of industries, from temperature and flow control to steam regulation and cavitation management. Their advanced design, combined with a wide range of materials and customizable features, makes them a go-to solution for industries looking to optimize operational performance and system efficiency. By adhering to strict industry standards and offering tailored solutions, V-Port Ball Control Valves continue to set the bar for excellence in flow control technology. Whether for industrial processes, energy-saving initiatives, or environmental safety, these valves provide a proven, reliable choice for any application.