On this page

Pneumatic control valves are indispensable components in industrial control systems, essential for maintaining operational safety and efficiency. They are extensively utilized to regulate critical parameters like pressure, flow rate, fluid level, and temperature within pipelines, ensuring precise control and optimization of production processes.

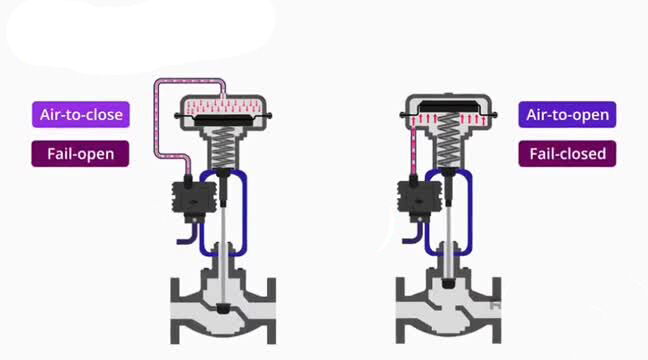

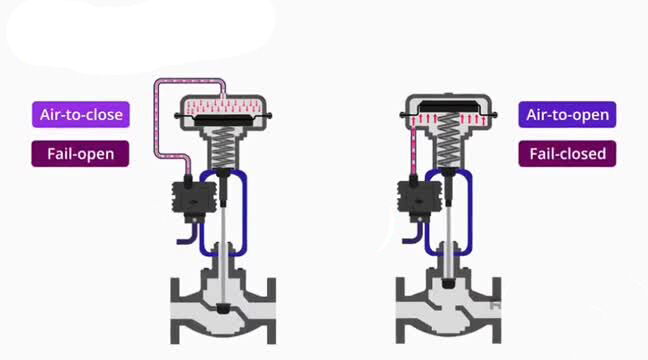

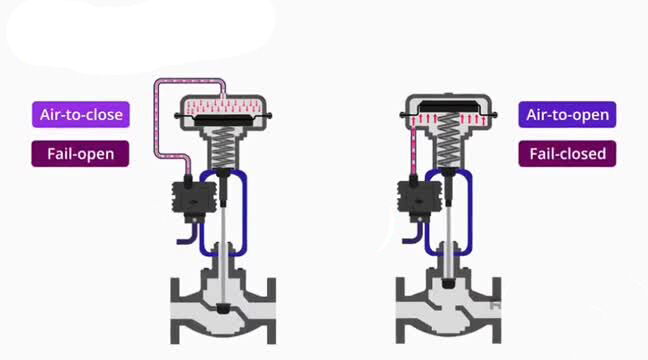

Operation: This type of control valve opens when the air pressure on the diaphragm head increases. As the input air pressure reaches its peak, the valve moves to its fully open position. Conversely, a decrease in air pressure causes the valve to close, and it remains fully closed when there's no input air. This characteristic makes it suitable for applications where safety demands closing the valve in case of air loss, such as in heating furnaces to prevent overheating if gas supply fails.

Alias: Also known as fault-closure valves due to their behavior of closing in the absence of air pressure.

Operation: Contrary to air-open valves, these valves close when air pressure increases and open fully when pressure decreases or is absent. They are preferred in applications where continuous flow is critical, such as ensuring cooling water continues to flow in heat exchange equipment even if air supply is interrupted.

Alias: Known as fault-opening valves because they open in the event of air pressure loss.

Crystallization and Solidification: Media prone to crystallizing or solidifying, or those containing solid particles, should use air-open valves to prevent valve blockage.

Corrosiveness and Temperature/Pressure: For corrosive or high-temperature/pressure media, select valves with materials and structures that withstand these conditions. Additionally, ensure robust control of the gas source.

Response Time and Frequency: Applications needing rapid response and frequent operation benefit from valves with short response times. These valves improve system accuracy and responsiveness.

Stability and Longevity: Processes requiring stability over extended periods should use reliable air-open/close valves to maintain consistent performance and minimize downtime.

Industry Standards: Industries with stringent safety requirements, such as chemical production, should opt for valves equipped with double seals or safety devices. These features prevent media leakage and valve failure, ensuring operational safety.

Medium Compatibility: Understand the characteristics of the fluid being controlled to choose appropriate valve materials and designs.

Process Optimization: Select valves based on specific process needs, considering factors like flow rates, pressure ranges, and operational cycles.

Maintenance and Reliability: Implement regular maintenance schedules to ensure valves operate efficiently throughout their service life. This practice enhances reliability and minimizes downtime.

FC: Valve closes upon gas supply loss.

FO: Valve opens upon gas supply loss.

FL: Valve maintains its position upon gas supply loss.

FC: Valve closes upon gas supply or solenoid valve power failure.

FO: Valve opens upon gas supply or solenoid valve power failure.

AFL/EFC: Valve maintains position upon gas supply loss but closes upon solenoid valve power failure.

AFL/EFO: Valve maintains position upon gas supply loss but opens upon solenoid valve power failure.

Choosing the right pneumatic control valve type—air open or air close—depends on factors such as medium characteristics, process requirements, and safety considerations. By selecting valves that align with these criteria and ensuring proper maintenance, industrial systems can achieve optimal performance, reliability, and safety in fluid parameter control.

Operation: This type of control valve opens when the air pressure on the diaphragm head increases. As the input air pressure reaches its peak, the valve moves to its fully open position. Conversely, a decrease in air pressure causes the valve to close, and it remains fully closed when there's no input air. This characteristic makes it suitable for applications where safety demands closing the valve in case of air loss, such as in heating furnaces to prevent overheating if gas supply fails.

Alias: Also known as fault-closure valves due to their behavior of closing in the absence of air pressure.

Operation: Contrary to air-open valves, these valves close when air pressure increases and open fully when pressure decreases or is absent. They are preferred in applications where continuous flow is critical, such as ensuring cooling water continues to flow in heat exchange equipment even if air supply is interrupted.

Alias: Known as fault-opening valves because they open in the event of air pressure loss.

Crystallization and Solidification: Media prone to crystallizing or solidifying, or those containing solid particles, should use air-open valves to prevent valve blockage.

Corrosiveness and Temperature/Pressure: For corrosive or high-temperature/pressure media, select valves with materials and structures that withstand these conditions. Additionally, ensure robust control of the gas source.

Response Time and Frequency: Applications needing rapid response and frequent operation benefit from valves with short response times. These valves improve system accuracy and responsiveness.

Stability and Longevity: Processes requiring stability over extended periods should use reliable air-open/close valves to maintain consistent performance and minimize downtime.

Industry Standards: Industries with stringent safety requirements, such as chemical production, should opt for valves equipped with double seals or safety devices. These features prevent media leakage and valve failure, ensuring operational safety.

Medium Compatibility: Understand the characteristics of the fluid being controlled to choose appropriate valve materials and designs.

Process Optimization: Select valves based on specific process needs, considering factors like flow rates, pressure ranges, and operational cycles.

Maintenance and Reliability: Implement regular maintenance schedules to ensure valves operate efficiently throughout their service life. This practice enhances reliability and minimizes downtime.

FC: Valve closes upon gas supply loss.

FO: Valve opens upon gas supply loss.

FL: Valve maintains its position upon gas supply loss.

FC: Valve closes upon gas supply or solenoid valve power failure.

FO: Valve opens upon gas supply or solenoid valve power failure.

AFL/EFC: Valve maintains position upon gas supply loss but closes upon solenoid valve power failure.

AFL/EFO: Valve maintains position upon gas supply loss but opens upon solenoid valve power failure.

Choosing the right pneumatic control valve type—air open or air close—depends on factors such as medium characteristics, process requirements, and safety considerations. By selecting valves that align with these criteria and ensuring proper maintenance, industrial systems can achieve optimal performance, reliability, and safety in fluid parameter control.