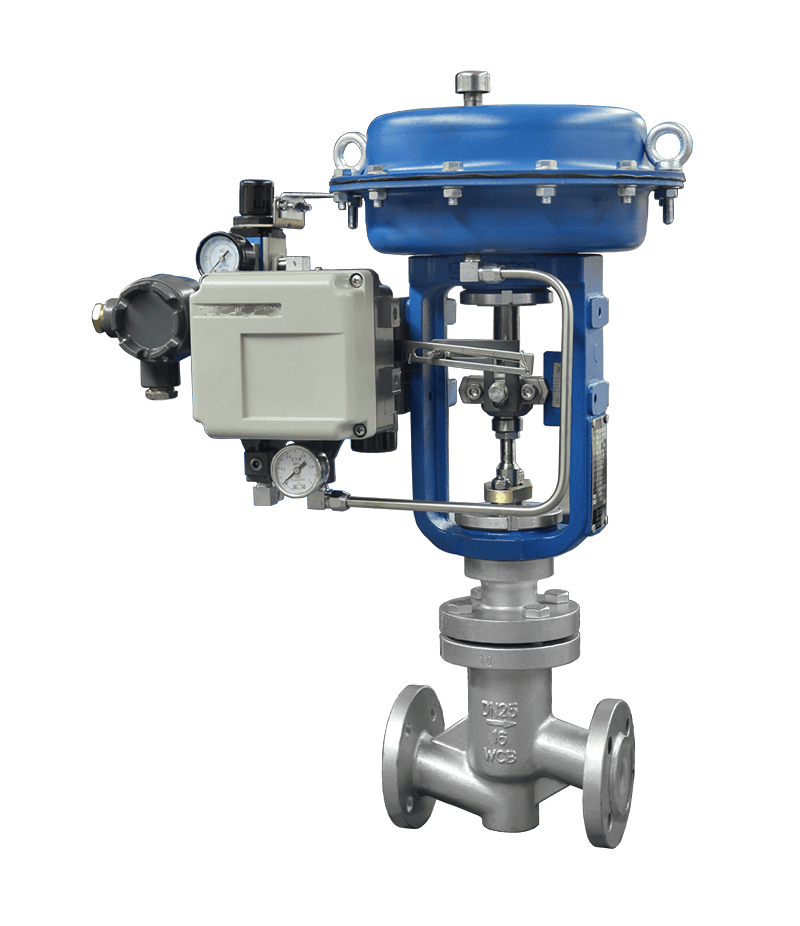

The pneumatic single-seat globe control valve is a highly efficient and reliable component widely used in process control systems. Featuring a top-guided structure equipped with a pneumatic diaphragm actuator, this valve type provides precise control over fluid flow, pressure, temperature, and level. The single-seat globe control valve’s flow port is designed in an S-shape, which ensures minimal pressure drop, a spacious valve cavity, accurate flow characteristics, and easy assembly and disassembly. Due to these advantages, it is especially suitable for applications where the differential pressure before and after the valve is not significant, and where precise regulation is essential.

Pneumatic globe control valves combine the inherent accuracy of globe valves with the automation capabilities of pneumatic actuation. By using compressed air or gas to operate the valve, systems can achieve remote control, rapid response, and seamless integration into automated process control systems. These valves are commonly employed in industries that demand high-precision control, including chemical processing, oil and gas, power generation, and pharmaceutical manufacturing.

A globe valve is a type of linear motion valve used primarily for throttling flow. The design features a spherical body cavity surrounding the port area, with a movable plug (or disc) that travels perpendicular to the flow path to regulate the passage of fluids. Globe valves are widely recognized for their ability to control flow accurately, making them ideal for processes that require fine adjustments of pressure, temperature, and fluid volume.

The pneumatic single-seat globe valve enhances this capability by combining a single-seat design with pneumatic actuation. The single-seat configuration consists of a single plug moving against a single seat, creating a streamlined flow path. This design minimizes turbulence, reduces pressure drop, and allows for precise control of process variables.

Many single-seat globe valve bodies incorporate a cage or cage-type construction. The cage serves multiple purposes:

It holds the seat ring in position.

It guides the plug to ensure consistent and accurate movement.

It allows customization of valve flow characteristics, such as linear, equal-percentage, or quick-opening flow patterns.

Furthermore, cage-type designs can be modified easily by replacing valve internals to adapt to specific process needs. Such modifications can provide reduced capacity flow, noise attenuation, or cavitation control, making these valves versatile for a wide range of industrial environments.

Pneumatic actuators use compressed air to generate motion and control the valve. Typically, a diaphragm actuator converts the air pressure into linear motion, which moves the valve plug to open, close, or modulate flow. By adjusting the pneumatic input, operators can precisely regulate fluid flow in response to system demands or control signals from a process controller.

Key benefits of pneumatic actuation include:

Rapid response: Pneumatic valves respond quickly to input signals, allowing precise and dynamic control of fluid systems.

Remote operation: Compressed air signals can be transmitted over long distances, enabling centralized control in industrial facilities.

Safety: Pneumatic systems are inherently safer in hazardous environments since they do not rely on electricity for actuation.

Durability: Pneumatic actuators can withstand harsh operating conditions, including high temperature, corrosive media, and fluctuating pressures.

The single-seated control valve is specifically designed to provide reliable, precise, and repeatable flow regulation. Its main components include the valve body, seat, plug, stem, and pneumatic actuator.

Key Features:

Streamlined Flow Path: Reduces turbulence and pressure drop, ensuring efficient fluid handling.

Accurate Flow Control: The single plug and seat design allows fine adjustments of flow rate and pressure.

Versatility: Suitable for controlling liquids, gases, and steam in various industrial applications.

Ease of Maintenance: The top-guided structure and modular design simplify assembly, disassembly, and maintenance.

Customizable Flow Characteristics: By changing the cage or plug, the flow pattern can be adjusted to meet specific process requirements.

Advantages:

Exceptional control over process variables such as flow, pressure, temperature, and level.

Reduced wear and longer service life due to smooth operation and minimal turbulence.

Ability to handle corrosive or aggressive fluids when constructed from appropriate materials.

Integration with automated process control systems for remote operation and monitoring.

Pneumatic single-seat globe control valves are used across a wide range of industries where precision flow control is critical.

In the oil and gas sector, these valves regulate hydrocarbon flow during extraction, processing, and transportation. Precise control is essential for safe and efficient operations, ensuring that pressure and flow rates remain within designated parameters. Pneumatic actuation allows operators to respond quickly to changes in process conditions, minimizing risk and improving system reliability.

Chemical plants rely on pneumatic control valves to manage aggressive chemicals and corrosive fluids. The valves deliver precise, repeatable control over flow rates, preventing chemical imbalances and ensuring consistent product quality. High-quality materials such as stainless steel or alloyed metals are often used to withstand chemical exposure and maintain valve longevity.

In power plants, pneumatic globe control valves regulate steam and cooling water flow, optimizing turbine performance and stabilizing power output. By maintaining precise control over fluid pressure and temperature, these valves improve energy efficiency and reduce operational stress on equipment.

Pharmaceutical processes require sterile and accurate fluid handling. Pneumatic single-seat globe valves provide tight control over flow rates, pressure, and temperature, which is essential for maintaining product integrity and meeting stringent regulatory standards.

Pneumatic globe valves are widely used in heating, ventilation, air conditioning (HVAC), and water treatment systems. They regulate chilled or hot water flow, control pressure in pipelines, and ensure precise temperature control in various applications.

In food and beverage processing, pneumatic single-seat globe valves ensure hygienic flow control for liquids, syrups, and other products. Their design allows for easy cleaning and maintenance while maintaining accurate process control.

Proper maintenance of pneumatic globe valves ensures optimal performance and long service life. Key maintenance practices include:

Regular Inspection: Periodically check the actuator, valve body, and internal components for wear, corrosion, or damage.

Lubrication: Ensure moving parts such as stems and plugs are adequately lubricated to prevent sticking and reduce friction.

Seal Replacement: Replace worn or damaged seals to maintain tight shutoff and prevent leakage.

Actuator Check: Verify that the pneumatic diaphragm or piston actuator is functioning correctly and responds to control signals.

Flow Calibration: Periodically recalibrate the valve to ensure accurate flow control and maintain process efficiency.

Common Troubleshooting Issues:

Leakage: Can result from damaged seats, plugs, or seals. Regular inspection and timely replacement of worn components can prevent leakage.

Slow Response: Often caused by air supply issues or actuator malfunction. Check air pressure and actuator functionality.

Noise or Vibration: May occur due to high flow velocity, cavitation, or improper installation. Cage modifications and flow adjustments can resolve these issues.

Q1: What is a single-seated control valve?

A single-seated control valve functions as a precise fluid flow regulator through its efficient design. The valve operates via a single plug that moves against a single seat to adjust flow rate. Its streamlined flow path minimizes turbulence and pressure drop, making it ideal for applications requiring exact control of process variables such as temperature, pressure, and flow.

Q2: What are the advantages of pneumatic control valves?

Pneumatic control valves offer rapid response, remote operation, and safety in hazardous environments. They provide precise, repeatable flow regulation and are durable under harsh operating conditions, including high temperatures and corrosive media.

Q3: What are typical applications of pneumatic control valves?

Oil and gas processing

Chemical and petrochemical industries

Power generation and steam control

Pharmaceutical manufacturing

Food and beverage processing

HVAC and water treatment systems

Q4: How do pneumatic actuators work?

Pneumatic actuators convert compressed air into linear or rotary motion. In globe valves, diaphragm actuators generate linear motion to move the valve plug, modulating flow according to control signals.

Q5: How is valve flow characterized?

Single-seat globe valves often use a cage-type design to establish specific flow characteristics. By adjusting the cage or replacing internals, the valve can achieve linear, equal-percentage, or quick-opening flow patterns, control cavitation, and reduce noise.

Pneumatic single-seat globe control valves represent a vital component in modern industrial process control systems. Their combination of precise throttling capabilities, pneumatic actuation, and modular design ensures efficient and reliable management of fluids in complex systems. With applications spanning oil and gas, chemical processing, power generation, pharmaceutical production, and more, these valves deliver exceptional accuracy, responsiveness, and durability.

The single-seat globe control valve’s ability to maintain stable flow, pressure, and temperature while minimizing pressure drop makes it an ideal choice for critical industrial processes. Coupled with proper maintenance and integration into automated control systems, pneumatic globe valves provide long-lasting, efficient, and safe operation across a wide range of industrial sectors.

By leveraging the advantages of pneumatic actuation and the precision of single-seat globe valve design, industries can achieve optimal control over their processes, ensuring product quality, system reliability, and operational efficiency.