In industrial environments, control valves are essential for controlling fluid flow in sectors such as oil and gas, chemical processing, power generation, water treatment, and manufacturing. They are vital in sectors such as oil and gas, chemical processing, power generation, water treatment, and manufacturing. The precision control and monitoring of these valves are paramount for operational efficiency, safety, and adherence to regulations. This is where the role of limit switches becomes significant.

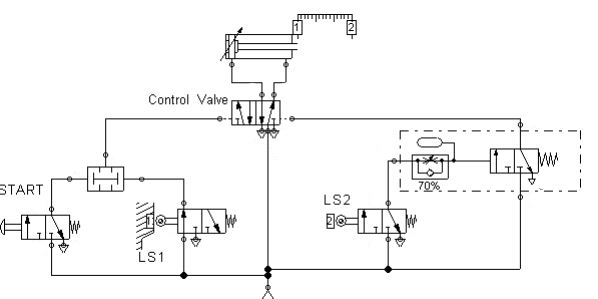

Limit switches are electromechanical devices that work in tandem with control valves, offering crucial feedback on their operational status. Installed at strategic points along the valve's movement path, they are triggered when the valve hits specific positions. Comprising a mechanical actuator and electrical contacts, these switches send signals to the control system, indicating the valve's exact position when activated.

The Integral Role of Limit Switches in Valve Management

Position Feedback: Limit switches provide precise information about the valve's position, signaling fully open, fully closed, or any intermediate state, which is vital for monitoring valve status.

Control System Synchronization: They are a key component of control systems that regulate valve operations, with signals from the switches allowing the system to make necessary adjustments to maintain desired conditions.

Safety and Reliability Enhancement: By ensuring valves operate within set parameters, limit switches prevent potential equipment damage or process disruptions that could arise from over- or under-travel.

Automation and Remote Operation: They support the automation of valve control processes, enabling remote or automatic operation based on pre-set conditions, which streamlines operations and reduces manual intervention.

Diagnostic Utility: Limit switches can identify operational irregularities such as valve sticking or excessive wear, serving as diagnostic tools that flag maintenance needs.

Applications Across Industries

Limit switches are extensively used in various sectors:

In Oil and Gas, they regulate flow in pipelines and refineries.

In Chemical Processing, they manage chemical flow and maintain process integrity.

In Power Generation, they control water and steam flow in critical systems.

In Water Treatment, they oversee water and chemical flow in purification processes.

In Manufacturing, they govern the flow of materials and fluids in production machinery.

Advancements in Limit Switch Technology

Recent technological advancements have bolstered the capabilities and reliability of limit switches:

Digital Communication Protocols: They now integrate with advanced protocols for more efficient communication with control systems.

Wireless Connectivity: The advent of wireless limit switches simplifies installation, especially in hard-to-reach or hazardous areas.

Integrated Sensors: Modern switches may include sensors for additional measurements, offering a broader insight into valve performance.

Additional Considerations

Limit switches also offer:

Emergency Shutdown: They can initiate emergency procedures in response to abnormal conditions.

Maintenance Alerts: They provide early warnings for maintenance needs, preventing unexpected downtime.

Redundancy: In critical systems, they may be installed redundantly to ensure continuous monitoring.

Environmental Monitoring: With integrated sensors, they can also monitor environmental factors for process optimization.

Conclusion

Limit switches are essential in valve regulation, offering a range of benefits from feedback on position to enhancing safety and enabling automation. Their widespread use across industries underscores their importance in ensuring the precise control of fluid flow. As technology progresses, the functionality and reliability of limit switches continue to improve, bolstering their contribution to the efficiency and safety of industrial processes. In essence, limit switches are a cornerstone of safe and efficient industrial valve operations, their versatility and significance undiminished by time.

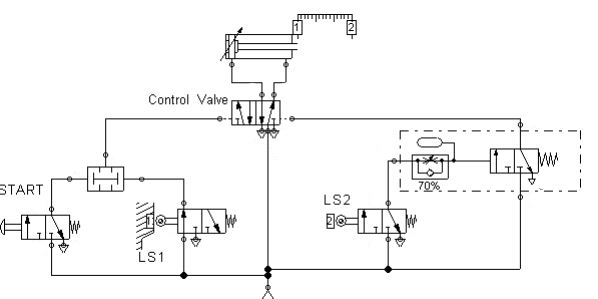

Limit switches are electromechanical devices that work in tandem with control valves, offering crucial feedback on their operational status. Installed at strategic points along the valve's movement path, they are triggered when the valve hits specific positions. Comprising a mechanical actuator and electrical contacts, these switches send signals to the control system, indicating the valve's exact position when activated.

The Integral Role of Limit Switches in Valve Management

Position Feedback: Limit switches provide precise information about the valve's position, signaling fully open, fully closed, or any intermediate state, which is vital for monitoring valve status.

Control System Synchronization: They are a key component of control systems that regulate valve operations, with signals from the switches allowing the system to make necessary adjustments to maintain desired conditions.

Safety and Reliability Enhancement: By ensuring valves operate within set parameters, limit switches prevent potential equipment damage or process disruptions that could arise from over- or under-travel.

Automation and Remote Operation: They support the automation of valve control processes, enabling remote or automatic operation based on pre-set conditions, which streamlines operations and reduces manual intervention.

Diagnostic Utility: Limit switches can identify operational irregularities such as valve sticking or excessive wear, serving as diagnostic tools that flag maintenance needs.

Applications Across Industries

Limit switches are extensively used in various sectors:

In Oil and Gas, they regulate flow in pipelines and refineries.

In Chemical Processing, they manage chemical flow and maintain process integrity.

In Power Generation, they control water and steam flow in critical systems.

In Water Treatment, they oversee water and chemical flow in purification processes.

In Manufacturing, they govern the flow of materials and fluids in production machinery.

Advancements in Limit Switch Technology

Recent technological advancements have bolstered the capabilities and reliability of limit switches:

Digital Communication Protocols: They now integrate with advanced protocols for more efficient communication with control systems.

Wireless Connectivity: The advent of wireless limit switches simplifies installation, especially in hard-to-reach or hazardous areas.

Integrated Sensors: Modern switches may include sensors for additional measurements, offering a broader insight into valve performance.

Additional Considerations

Limit switches also offer:

Emergency Shutdown: They can initiate emergency procedures in response to abnormal conditions.

Maintenance Alerts: They provide early warnings for maintenance needs, preventing unexpected downtime.

Redundancy: In critical systems, they may be installed redundantly to ensure continuous monitoring.

Environmental Monitoring: With integrated sensors, they can also monitor environmental factors for process optimization.

Conclusion

Limit switches are essential in valve regulation, offering a range of benefits from feedback on position to enhancing safety and enabling automation. Their widespread use across industries underscores their importance in ensuring the precise control of fluid flow. As technology progresses, the functionality and reliability of limit switches continue to improve, bolstering their contribution to the efficiency and safety of industrial processes. In essence, limit switches are a cornerstone of safe and efficient industrial valve operations, their versatility and significance undiminished by time.