Key Specifications / Features

- Hits: 22

- Categories: Ball Control Valves

- Tags: Stainless Steel Ball Control Valve, SS 316 Ball Control Valve, 1 Inch Ball Control Valve

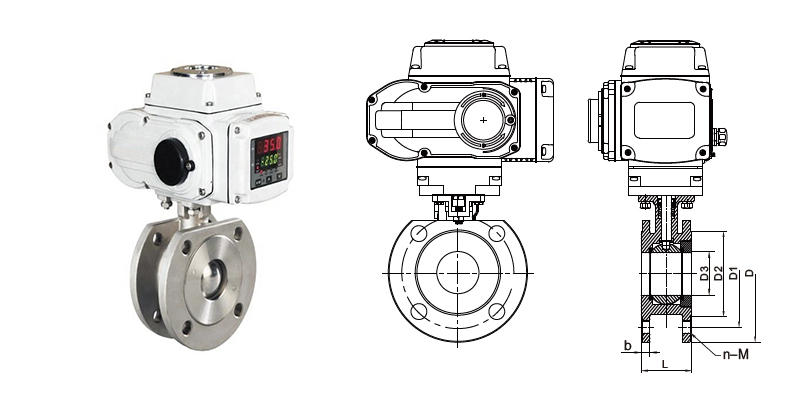

Product Name: Stainless Steel Ball Control Valve

Material: Stainless Steel 304, 316, SS 304, SS 316

Seat Material: PTFE, Nylon, PPL

Nominal Size: 1-4 Inch, DN25-DN100

Pressure Rating: Class 150 LB, PN20

Connection Type: Flanged

Working Temperature: 40°C - 180°C

Electric Actuator: On/Off, Regulation, Intelligent, Multi-Turn, Explosion-proof

Applications: Water Treatment, Oil & Gas, Biotechnology, etc

Electric Actuator Features:

Manual Function: Equipped with a handwheel for manual operation.

Switch Type: Offers adjustable and intelligent actuators, enabling remote control to reduce labor costs.

Temperature Resistance: Handles temperatures from -30℃/86℉ to 180℃/356℉.

Certification: ISO 5211 and Namur international installation standard for easy installation and maintenance.

Valve Body Features:

Ball Valve Types: Available in 2-way and 3-way configurations with thread, flange, clamp, or welding connections.

Material Options: Made from Stainless Steel 304, 304L, 316, or 316L.

Low Fluid Resistance: Provides minimal resistance, similar to a pipe segment of the same length.

Standard: Conforms to GB/ANSI/JIS/DIN standards.

Special Requirements: Customizable for high pressure, high temperature, and strong corrosion environments.