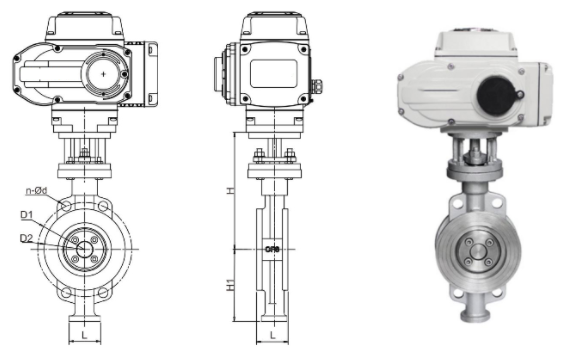

Product Name: Triple Eccentric Butterfly Control Valve

Material: Stainless Steel

Seat Material: PTFE, Nylon, PPL

Nominal Size: 2-8 Inch, DN50-DN200

Pressure Rating: Class 150 LB, PN10, PN16

O Ring: PTFE

Connection Type: Worm Gear

Working Temperature: -30°C - 180°C

Applications: Water Treatment, Oil & Gas, Biotechnology, etc

Key Benefits:

Fast Delivery: Standard products are readily available in stock.

ODM Service: Customization options to meet specific needs.

One-stop Solution: Comprehensive range of accessories to boost efficiency.

Quality Assurance: Certified with CE and ISO9000, ensuring high-quality actuators and valves.

Cost-effectiveness: Long service life reduces maintenance and replacement costs.

Full Bore: Ensures stable flow rate and consistent pressure values.

Anti-leakage: Superior sealing minimizes the risk of leaks.

Space Efficiency: Compact size requires less site area.

Features of Our Butterfly Valve:

Construction: Pinless, compact 2-section valve stem structure.

Maintenance: Easy maintenance and disassembly procedures.

Anti-leakage Design: Stem seal prevents common leakage issues.

Operational Efficiency: Smooth and rapid opening and closing with minimal fluid resistance.

Low Pressure Drop: Ensures minimal resistance to fluid flow.

Customization Options: Capable of meeting high-pressure, high-temperature, and corrosive environment requirements.