In the world of industrial automation and fluid control, pneumatic butterfly valves have become indispensable. Their compact design, reliable performance, and ability to regulate a wide range of media make them a key component in pipelines across diverse industries—including water treatment, chemical processing, oil and gas, power generation, HVAC systems, and food and beverage manufacturing.

Unlike manually operated valves, pneumatic butterfly valves are driven by compressed air, which allows for faster, more precise control over fluid flow. They play a crucial role in helping engineers design systems that are more efficient, safe, and cost-effective, especially where frequent operation and remote automation are required.

In this comprehensive guide, we’ll explore what pneumatic butterfly valves are, how they work, the different types available, their key components, advantages, limitations, and practical applications. Whether you are a seasoned engineer, a plant operator, or someone new to the field, this article aims to give you an in-depth understanding of the functionality and importance of pneumatic butterfly valves in modern industry.

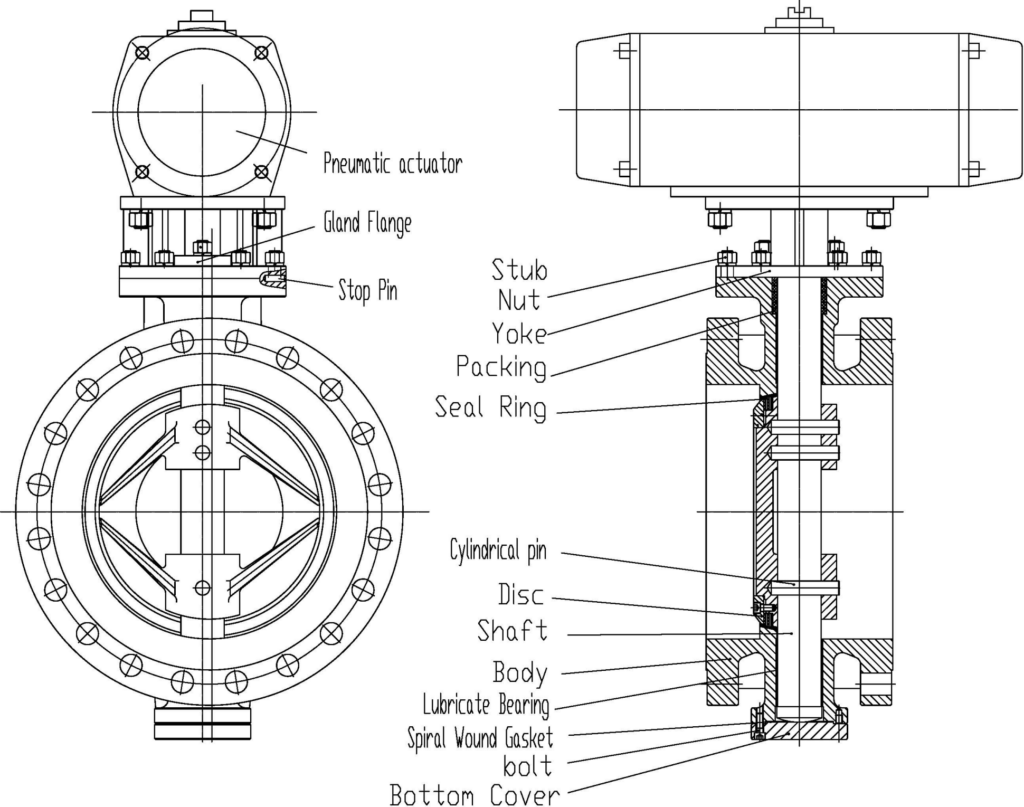

A pneumatic butterfly valve is a type of quarter-turn valve that uses a pneumatic actuator to open or close a disk positioned in the center of the pipe. When air pressure is applied to the actuator, the valve disk rotates on a shaft to either permit or obstruct the flow of fluids (liquids, gases, or slurries). The actuator can be either single-acting or double-acting, depending on the level of control and reliability required.

These valves are known for their simplicity, compact structure, and rapid response, making them ideal for applications where fast and frequent operation is needed.

Let’s examine a representative example of a pneumatic butterfly valve assembly to better understand its construction and performance:

Valve Size: 65 mm (2-1/2 inch) nominal diameter

Media Compatibility: Suitable for liquids and gases

Temperature Range: -10°C to +110°C

Maximum Pressure: 16 bar

Actuator Torque: 49.6 Nm at 8 bar

Control Pressure: 6 – 10 bar

Connection Type: Wafer type

Actuator Operation: Double acting, rack-and-pinion

Valve Body Material: Cast iron

Disc Material: Cast iron

Seal Material: EPDM

Actuator Housing: Anodized aluminum

Air Supply Ports: G1/8

Mounting Standard: ISO 5211 F05 flange (11 mm)

ATEX Certification: II 2G Ex d C (for explosive environments)

Additionally, this valve can be paired with a 1/4" Namur solenoid valve, allowing for direct air supply control. A mechanical position indicator and optional limit switch box can also be mounted to monitor and control valve position remotely.

The operation of a pneumatic butterfly valve is based on the simple principle of using pressurized air to create rotary motion. Here's a step-by-step breakdown of how the valve functions:

Compressed air is delivered to the pneumatic actuator, typically via a solenoid valve mounted using Namur interface. In a double-acting actuator, air alternately enters and exits two chambers to rotate the internal piston in either direction. In a single-acting actuator, a spring returns the valve to its default position when air pressure is removed.

Inside the actuator, the pressurized air pushes pistons connected to a rack, which then rotates a pinion gear. This gear is directly connected to the valve stem (shaft).

As the shaft turns, it rotates the disc within the valve body. In the open position, the disc aligns with the flow direction to minimize resistance. In the closed position, the disc turns perpendicular to block the flow entirely.

An EPDM seal ring ensures tight shut-off by preventing media from leaking past the disc. The shaft is sealed with packing materials compressed by a gland flange to maintain internal pressure integrity.

A lubricated bearing reduces friction and wear during rotation.

A bottom cover and stub nut help secure internal components and maintain alignment.

A position indicator visually shows whether the valve is open or closed.

Wafer butterfly valves are the most common design, installed between two pipe flanges using through bolts. They are lightweight, compact, and cost-effective, but not suitable for end-of-line service.

Lug-type butterfly valves have threaded inserts on both sides of the valve body, allowing them to be bolted directly between flanges. These can be used in dead-end service and offer more flexibility during maintenance.

Flanged butterfly valves feature flanged ends that bolt directly to pipe flanges. They are more robust and easier to align during installation but are bulkier and heavier than wafer or lug types.

These valves incorporate an eccentric disc design that improves sealing, reduces wear, and allows operation at higher pressures and temperatures.

Pneumatic butterfly valves offer numerous benefits that make them highly attractive for industrial systems:

Quarter-turn design allows rapid opening and closing within seconds.

Slim profile makes them ideal for tight installations and space-constrained environments.

Compatible with PLC systems and remote-control stations using solenoid valves and limit switches.

Can be safely used in hazardous environments with explosive gases or dust.

Compared to electric actuators, pneumatic systems are generally more affordable upfront.

Can handle a wide range of fluids, including corrosive chemicals and slurries, depending on the material selection.

While pneumatic butterfly valves are highly efficient, they are not without drawbacks:

These valves need a compressed air system to function, which adds to installation complexity.

Double-acting actuators use more compressed air compared to single-acting or electric actuators.

Although cheaper initially, the ongoing cost of air compression may exceed that of an electric actuator over time.

Pneumatic butterfly valves serve a wide array of industrial and commercial systems:

Used in flow regulation and shut-off functions in water distribution, filtration, and sludge handling.

Control of aggressive or hazardous fluids where automated, ATEX-rated solutions are required.

Used for CIP (clean-in-place) systems, hygienic fluid transfer, and ingredient control.

Ensures precise fluid handling in cleanroom and sterile processing environments.

Used for chilled water or air-handling systems for zone isolation and flow modulation.

Used in steam, cooling water, and ash handling systems in thermal or nuclear plants.

Proper installation and regular maintenance are essential for ensuring long service life and optimal performance:

Always align the valve properly with piping. Use the correct flange type and torque bolts evenly to avoid damage to the seal.

Ensure the solenoid valve is mounted according to the Namur standard and is compatible with the actuator’s pressure rating.

Bearings and seals should be inspected and lubricated periodically to minimize wear.

After installation, conduct leak tests to ensure the valve seals properly in both open and closed positions.

Install a limit switch box or positioner for feedback on valve status, especially for automated systems.

Pneumatic butterfly valves are a cornerstone of automated flow control systems across a wide range of industries. Their fast actuation, reliability, and compatibility with industrial automation make them a top choice for engineers looking to optimize system performance.

Whether used in a chemical plant, water facility, or manufacturing line, these valves deliver dependable performance with minimal maintenance. When correctly selected and installed, a pneumatic butterfly valve can serve reliably for many years, reducing downtime and improving operational efficiency.

As automation continues to advance, pneumatic butterfly valves will remain essential tools in the transition toward smarter, more sustainable industrial infrastructure.