On this page

In fluid control systems, precise pressure control is essential to ensure the system's operational efficiency and safety. The role of self-operated pressure control valves as a key component designed to automatically regulate system pressure in the absence of an external power supply or complex control system cannot be ignored. This paper will discuss the function, advantage, application and maintenance method of self-operated pressure control valve in detail.

A self-operated pressure control valve is a valve that can automatically adjust the pressure in the system without the need for an external power supply or complex control system. Unlike valves that require external control signals or electrical support, these valves operate on their own, relying on pressure within the system. Pressure sensors and actuators built into the valve detect and adjust the pressure in real time to maintain the set pressure level, thus ensuring stable system operation.

The valve is designed to simplify operation and reduce costs. Because of its self-operating characteristics, self-operated pressure control valves are particularly easy to install and operate, making them widely used in many applications.

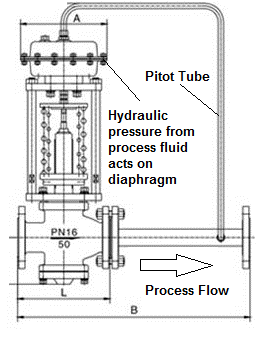

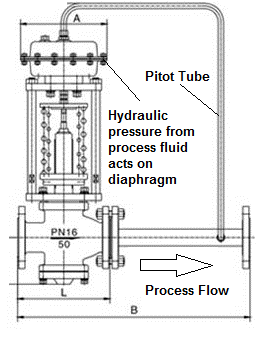

Self-operated pressure control valves maintain pressure stability in the system through a built-in automatic feedback mechanism. This mechanism first monitors changes in system pressure in real time through pressure sensors, such as diaphragm sensors. The detected pressure information is then passed to the valve actuator, which adjusts the valve opening based on this data. If the system pressure is too high, the actuator will reduce the valve opening to reduce the pressure; If the pressure is too low, increase the opening to raise the pressure. The valve constantly adjusts its position to maintain the set pressure level, ensuring efficient and stable operation of the system. This self-regulating capability eliminates the need for an external control system for self-operated pressure control valves, simplifying design and reducing installation costs.

Self-operated pressure control valves maintain pressure stability in the system through a built-in automatic feedback mechanism. This mechanism first monitors changes in system pressure in real time through pressure sensors, such as diaphragm sensors. The detected pressure information is then passed to the valve actuator, which adjusts the valve opening based on this data. If the system pressure is too high, the actuator will reduce the valve opening to reduce the pressure; If the pressure is too low, increase the opening to raise the pressure. The valve constantly adjusts its position to maintain the set pressure level, ensuring efficient and stable operation of the system. This self-regulating capability eliminates the need for an external control system for self-operated pressure control valves, simplifying design and reducing installation costs.

Self-operated pressure control valves have a number of significant advantages that make them a popular choice in fluid control systems. One of the biggest advantages of self-operated pressure control valves is that they do not require external power or control signals. This design relies on the pressure within the system to operate automatically, making the valve more economical and easy to install. Since no external controllers or electrical connections are required, installation costs are significantly reduced. This also simplifies the overall design of the system and reduces the need for supporting equipment. The automatic adjustment mechanism ensures the stability and reliability of pressure control. This reduces system instability caused by pressure fluctuations and improves the overall performance of the system. Self-operated pressure control valves are very easy to operate because they do not require complex setup or control adjustments. The built-in mechanism automatically handles all pressure regulation tasks, making the operation more straightforward and efficient. Because the valve design is simplified and there are fewer external components, maintenance work is also relatively reduced and less complicated. This simplified design helps reduce maintenance costs and frequency. In municipal water and wastewater treatment plants, self-operated pressure control valves help maintain a steady pressure in the pipeline, thus ensuring efficient and stable treatment processes. In heating, ventilation and air conditioning systems, these valves are used to regulate the pressure in the fluid distribution system to improve the overall system efficiency and ensure a comfortable indoor environment. In industrial processes such as chemical manufacturing, oil and gas, self-operated pressure control valves are used to maintain the required pressure levels to ensure safe and efficient operations. Self-operated pressure control valves are also used to protect the pump by regulating the pressure on the discharge side to prevent overpressure conditions that can cause pump damage. Stainless steel is known for its excellent corrosion resistance and strength and is suitable for handling corrosive fluids or high temperature applications. Brass is often used in water and general industrial applications because of its good workability and corrosion resistance. Bronze, with its durability and wear resistance, is suitable for applications in a variety of industrial environments. In some applications involving aggressive fluids, the risk of corrosion and chemical reactions can be reduced by using plastic materials such as PVC or CPVC, which provide an effective solution under specific conditions. Setting a pressure set point for a self-operated pressure control valve usually involves using a regulating screw or dial to set the required pressure level. By rotating these adjusting devices, the opening of the valve can be adjusted to achieve the appropriate pressure setting. In order to ensure that the valve can accurately maintain the required pressure, accurate operational calibration is critical. This usually requires adjustment and calibration following the guidance provided by the manufacturer to ensure that the valve achieves optimal performance in practical applications. In order to maintain the efficiency and stability of self-operated pressure control valves, regular maintenance work is indispensable. This usually means checking the valves regularly for leaks and making sure everything is sealed properly; Also pay attention to whether the valve is sensitive to pressure changes to ensure that it can be steadily maintained at the set pressure point. At the same time, it is also important to keep the valve clean, so as to prevent dust and debris from interfering with its normal work. Finally, don't forget to check the various parts of the valve, if found to be worn or damaged, such as seals or diaphragms, timely replacement, so that the valve can continue to maintain good working condition. Self-operated pressure control valves are generally suitable for medium pressure applications, while high pressure environments may require specially designed high pressure valves or other pressure control solutions. Choosing a valve that meets a specific pressure requirement is critical to ensuring the safety and reliability of the system.

When selecting a self-operated pressure control valve, the following key factors should be considered: First, confirm that the pressure range of the valve can meet the pressure required by the system; Secondly, ensure that the valve material is compatible with the type of fluid being controlled to avoid corrosion and damage; In addition, select valves that can work effectively under the required temperature conditions to adapt to different operating environments; In addition, the size of the valve should match the flow rate and pipe size of the system to achieve the best control effect; Finally, consider the specific requirements of the system, including installation space and operational requirements, to select the most suitable valve. As a key component of the fluid control system, self-operated pressure control valves play an important role in various applications because of their advantages such as no external power supply, self-regulation and easy operation. Through an automated pressure regulation mechanism, these valves effectively maintain the pressure stability of the system, thereby improving the efficiency and reliability of the system.

When selecting and applying self-operated pressure control valves, factors such as their material, pressure range, fluid type and system requirements are taken into account to ensure optimal performance in actual operation. At the same time, regular maintenance and inspection is also the key to ensure long-term stable operation of the valve.

Whether in water and wastewater treatment, HVAC systems, industrial processes or pump protection, self-contained pressure control valves provide a reliable solution to meet the needs of different systems. With the right selection and maintenance, self-operated pressure control valves will continue to play an irreplaceable role in the field of fluid control, escorting the efficient and safe operation of various systems.

The valve is designed to simplify operation and reduce costs. Because of its self-operating characteristics, self-operated pressure control valves are particularly easy to install and operate, making them widely used in many applications.

Self-operated pressure control valves maintain pressure stability in the system through a built-in automatic feedback mechanism. This mechanism first monitors changes in system pressure in real time through pressure sensors, such as diaphragm sensors. The detected pressure information is then passed to the valve actuator, which adjusts the valve opening based on this data. If the system pressure is too high, the actuator will reduce the valve opening to reduce the pressure; If the pressure is too low, increase the opening to raise the pressure. The valve constantly adjusts its position to maintain the set pressure level, ensuring efficient and stable operation of the system. This self-regulating capability eliminates the need for an external control system for self-operated pressure control valves, simplifying design and reducing installation costs.

Self-operated pressure control valves maintain pressure stability in the system through a built-in automatic feedback mechanism. This mechanism first monitors changes in system pressure in real time through pressure sensors, such as diaphragm sensors. The detected pressure information is then passed to the valve actuator, which adjusts the valve opening based on this data. If the system pressure is too high, the actuator will reduce the valve opening to reduce the pressure; If the pressure is too low, increase the opening to raise the pressure. The valve constantly adjusts its position to maintain the set pressure level, ensuring efficient and stable operation of the system. This self-regulating capability eliminates the need for an external control system for self-operated pressure control valves, simplifying design and reducing installation costs.Self-operated pressure control valves have a number of significant advantages that make them a popular choice in fluid control systems. One of the biggest advantages of self-operated pressure control valves is that they do not require external power or control signals. This design relies on the pressure within the system to operate automatically, making the valve more economical and easy to install. Since no external controllers or electrical connections are required, installation costs are significantly reduced. This also simplifies the overall design of the system and reduces the need for supporting equipment. The automatic adjustment mechanism ensures the stability and reliability of pressure control. This reduces system instability caused by pressure fluctuations and improves the overall performance of the system. Self-operated pressure control valves are very easy to operate because they do not require complex setup or control adjustments. The built-in mechanism automatically handles all pressure regulation tasks, making the operation more straightforward and efficient. Because the valve design is simplified and there are fewer external components, maintenance work is also relatively reduced and less complicated. This simplified design helps reduce maintenance costs and frequency. In municipal water and wastewater treatment plants, self-operated pressure control valves help maintain a steady pressure in the pipeline, thus ensuring efficient and stable treatment processes. In heating, ventilation and air conditioning systems, these valves are used to regulate the pressure in the fluid distribution system to improve the overall system efficiency and ensure a comfortable indoor environment. In industrial processes such as chemical manufacturing, oil and gas, self-operated pressure control valves are used to maintain the required pressure levels to ensure safe and efficient operations. Self-operated pressure control valves are also used to protect the pump by regulating the pressure on the discharge side to prevent overpressure conditions that can cause pump damage. Stainless steel is known for its excellent corrosion resistance and strength and is suitable for handling corrosive fluids or high temperature applications. Brass is often used in water and general industrial applications because of its good workability and corrosion resistance. Bronze, with its durability and wear resistance, is suitable for applications in a variety of industrial environments. In some applications involving aggressive fluids, the risk of corrosion and chemical reactions can be reduced by using plastic materials such as PVC or CPVC, which provide an effective solution under specific conditions. Setting a pressure set point for a self-operated pressure control valve usually involves using a regulating screw or dial to set the required pressure level. By rotating these adjusting devices, the opening of the valve can be adjusted to achieve the appropriate pressure setting. In order to ensure that the valve can accurately maintain the required pressure, accurate operational calibration is critical. This usually requires adjustment and calibration following the guidance provided by the manufacturer to ensure that the valve achieves optimal performance in practical applications. In order to maintain the efficiency and stability of self-operated pressure control valves, regular maintenance work is indispensable. This usually means checking the valves regularly for leaks and making sure everything is sealed properly; Also pay attention to whether the valve is sensitive to pressure changes to ensure that it can be steadily maintained at the set pressure point. At the same time, it is also important to keep the valve clean, so as to prevent dust and debris from interfering with its normal work. Finally, don't forget to check the various parts of the valve, if found to be worn or damaged, such as seals or diaphragms, timely replacement, so that the valve can continue to maintain good working condition. Self-operated pressure control valves are generally suitable for medium pressure applications, while high pressure environments may require specially designed high pressure valves or other pressure control solutions. Choosing a valve that meets a specific pressure requirement is critical to ensuring the safety and reliability of the system.

When selecting a self-operated pressure control valve, the following key factors should be considered: First, confirm that the pressure range of the valve can meet the pressure required by the system; Secondly, ensure that the valve material is compatible with the type of fluid being controlled to avoid corrosion and damage; In addition, select valves that can work effectively under the required temperature conditions to adapt to different operating environments; In addition, the size of the valve should match the flow rate and pipe size of the system to achieve the best control effect; Finally, consider the specific requirements of the system, including installation space and operational requirements, to select the most suitable valve. As a key component of the fluid control system, self-operated pressure control valves play an important role in various applications because of their advantages such as no external power supply, self-regulation and easy operation. Through an automated pressure regulation mechanism, these valves effectively maintain the pressure stability of the system, thereby improving the efficiency and reliability of the system.

When selecting and applying self-operated pressure control valves, factors such as their material, pressure range, fluid type and system requirements are taken into account to ensure optimal performance in actual operation. At the same time, regular maintenance and inspection is also the key to ensure long-term stable operation of the valve.

Whether in water and wastewater treatment, HVAC systems, industrial processes or pump protection, self-contained pressure control valves provide a reliable solution to meet the needs of different systems. With the right selection and maintenance, self-operated pressure control valves will continue to play an irreplaceable role in the field of fluid control, escorting the efficient and safe operation of various systems.